Agricultural plants begin life as fragile seeds that must be handled with meticulous care. Each step of the seed conditioning process is critical to...

Specialty Seed and Grain Conditioning Equipment

Enhance your seeds, grasses, and grains with specialty processing equipment designed by Cimbria, an industry-leading processing equipment manufacturer.

Brush Machine

The brush machine is ideal for handling grass seeds and clover, separating double grasses and removing the tails from the germ end of oats. This machine is designed with a modular system so that it can be used in a variety of applications.

Brush Machine Features

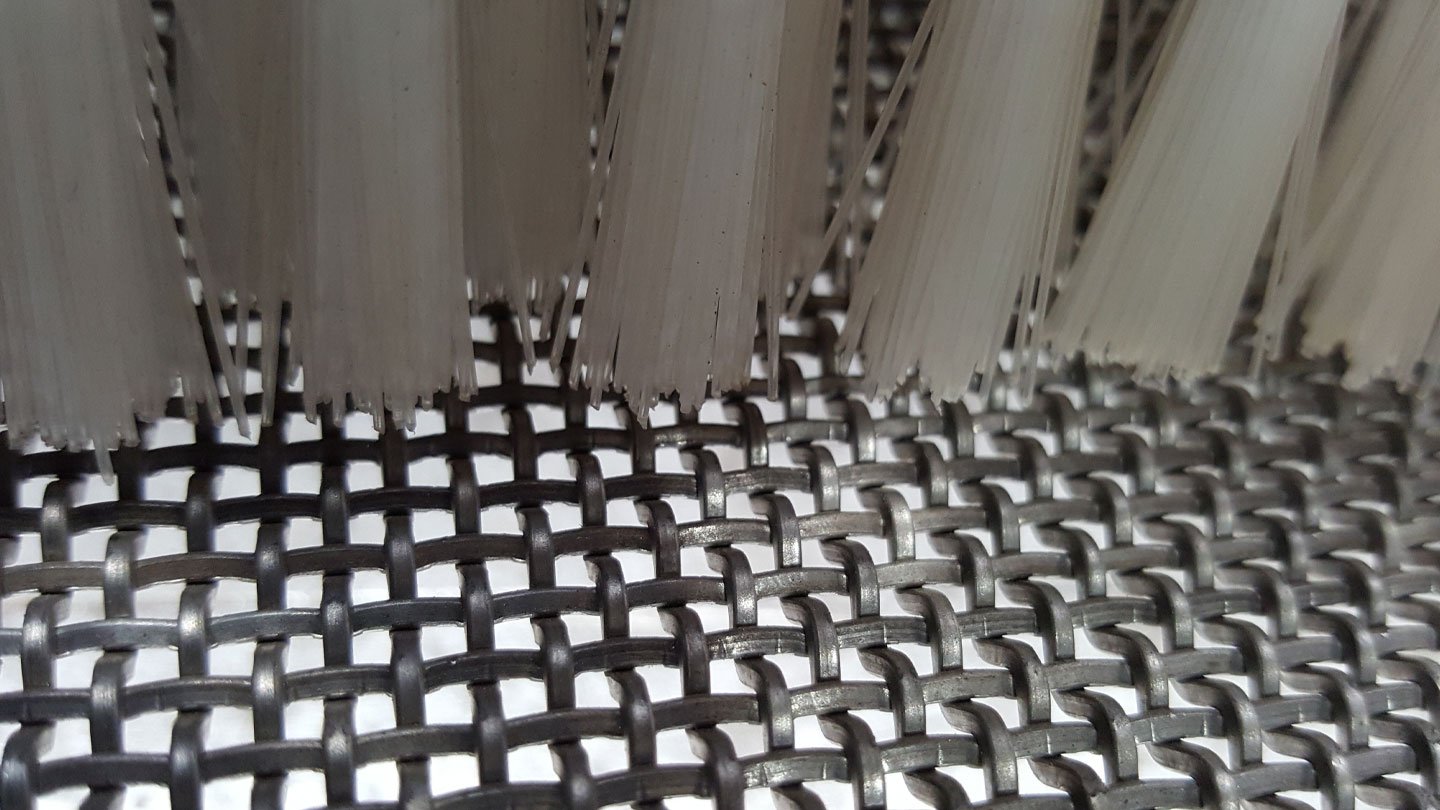

- Each cylinder is equipped with four heat resistant brushes to sweep the inner surface of the basket

- Each basket consists of a two-part easily interchangeable mesh and is available in various materials and perforations

- Completely enclosed and dust-proof machine

- Modular design

Brush Machine Benefits

Brush machines are used to separate awns, glumes, break-up doubles, and polish seeds, grasses, and grains. In general, these machines prepare the material for further processing by removing appendages.

Material Types

- Seeds

- Grains

De-Awner

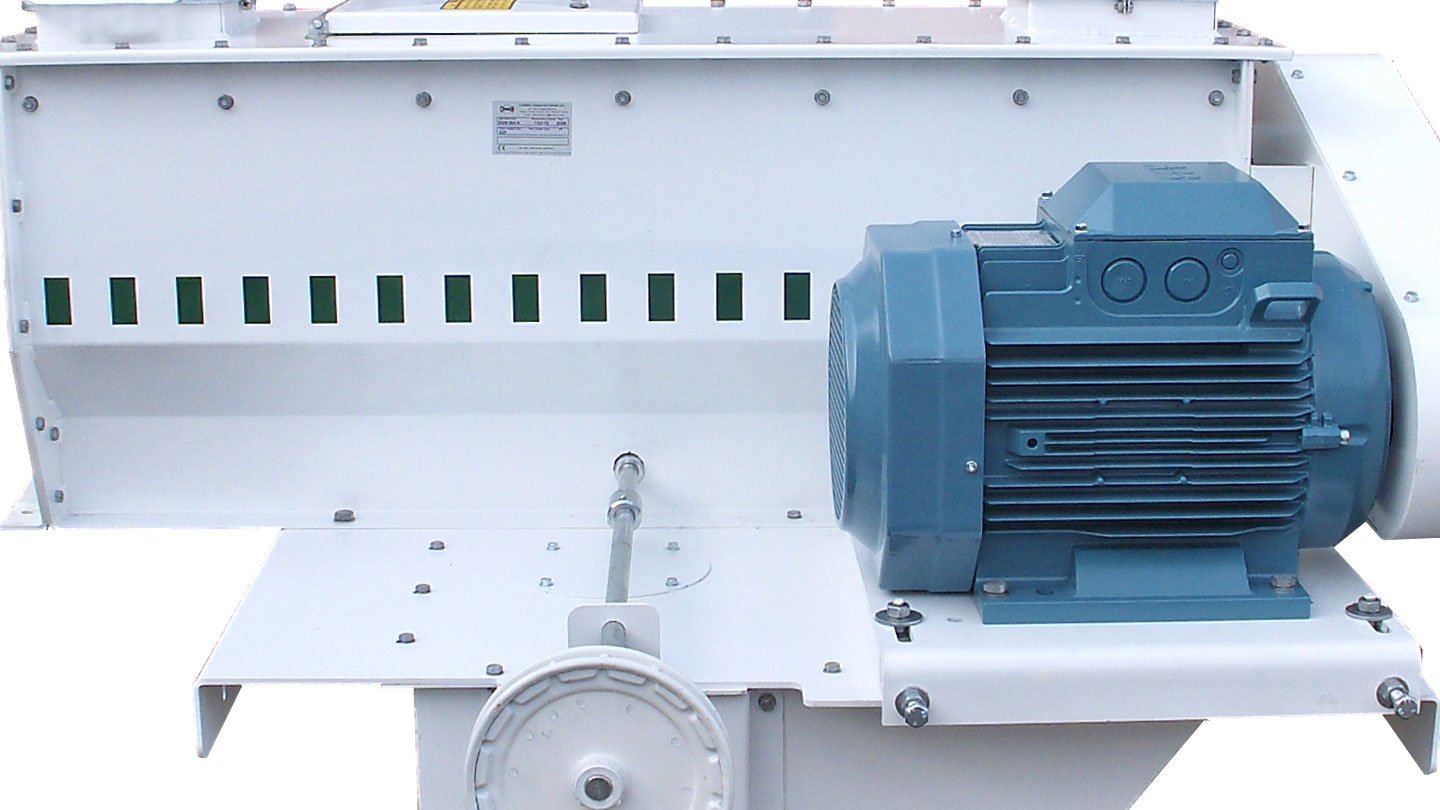

The Cimbria De-Awner is designed to treat malting barley, seed, grain, and other seed varieties. This machine is completely enclosed in a steel case with an agitator and removes impurities like beards from barley or separate double kernels in wheat.

De-Awner Features

Fully enclosed, rigid steel case

Staggered, steel beater bars

Adjustable discharge shutter

Bypass Inlet for materials that do not need treatment

De-Awner Benefits

Cimbria Deawners are commonly utilized to de-awn barley, clip oats, break up doubles and clusters, remove stems and for surface polishing of grains and vegetable seeds to improve appearance and increase the bushel weight. The cluster-breaking action greatly improves the performance of subsequent machines in the process flow.

Material Types

- Barley

- Grass Seed

- Grains

- Milo

- Oats

- Vegetable Seed

Velvet Roller

The velvet roller is designed for separating smooth coated seed from seed that has a surface texture like sorrel seed from the seed of trefoil plants, like clover or alfalfa. It can also remove weed seeds from good seeds, shrunken or unripe seeds and seed fragments.

Velvet Roller Features

Adjustable Inclination

Adjustable drive speed

Twin rolls covered in velvet

Includes 10 pairs of rolls

Capacity up to 440 lbs. per hour

Velvet Roller Benefits

Built for specialty seed cleaning applications only possible by separating based on differences in texture.

Material Types

- Dry Beans

- Forage Seeds

- Grains

Belt Sorter

The belt sorter separates round from flat or long kernels based on its rolling characteristics. It also frees sugar beet seed, peas, soybeans from half-broken, sticks, or twins through this sorting process. The belt sorter is designed with a modular construction that can be expanded in the future to accomodate a range of applications and capacities.

Belt Sorter Features

- Vibratory Feeder

- Adjustable Incline Position

- Adjustable Belt Speed

- Separates Kernels into two fractions

- Modular design for varying capacity needs

- Adaptable to Product by Use of Belts with Different Surface Texture

Belt Sorter Benefits

The belt sorter is beneficial for its overview of the sorting process due to the open view of the surface on the sorting belts. This machine has a simple but effective design and is very user-friendly and adjustable.

Material Types

- Sugar beet seed

- Peas

- Soybean

- Kernels

Ear Corn Sheller

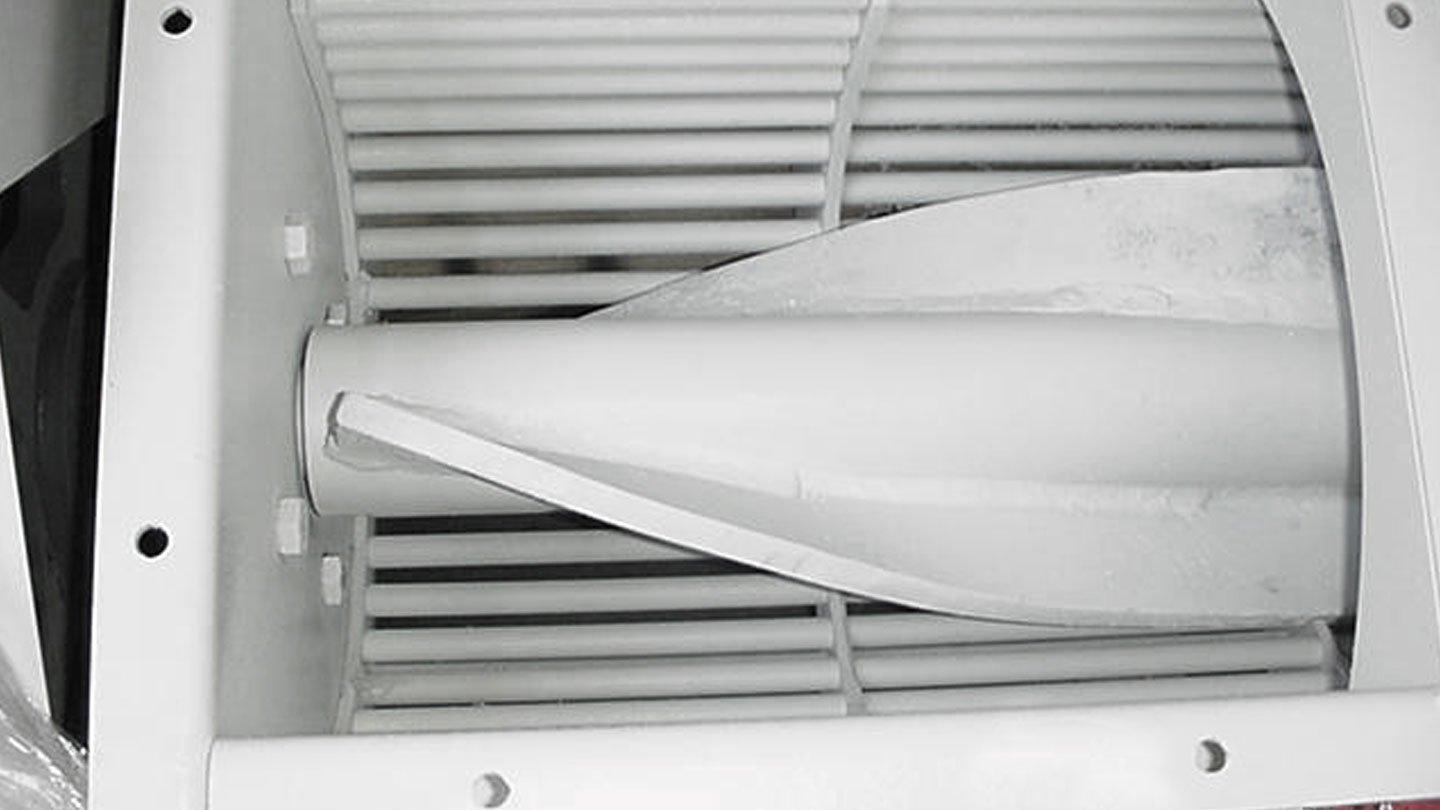

Bratney Ear Corn Shellers are designed to remove the kernels gently from the cob with the highest degree of efficiency. The shelling chamber features a semi-circular cage equipped with round bars. The shaft has a unique design to ensure gentle conveyance and durability. The combination machine includes an aspiration system and a drum style cleaner that allow the kernels to be cleaned before bulk storage.

Ear Corn Sheller Features

- Gentle Shelling

- Strategic Multiple Point Aspiration System

- Modular Design for More Versatility

- Enclosed System Design for Efficient Dust Control and Enhanced Safety

- Multiple Inspection Points\

- Quick Screen Release System

- Eliminates Dynamic Load/Vibration Issues

Ear Corn Sheller Benefits

Bratney’s ear corn sheller was designed to solve the unique challenges of ear corn shelling and increase the precision and quality of your end products more efficiently and cost-effectively.

Material Types

- Corn

- Popcorn

Let's Talk

We want to help you find the right fit for your specialty conditioning equipment. Reach out to our team to discuss your needs so we can help you discover the right equipment for you..

Contact UsResources

Seed treatment is a cornerstone of modern agriculture. It enhances crop productivity, ensuring farmers get the most out of every seed. By leveraging...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.