Agricultural plants begin life as fragile seeds that must be handled with meticulous care. Each step of the seed conditioning process is critical to...

Color Sorting Equipment for Seed, Grain, Edible, and Industrial Products

Achieve highly accurate and high-capacity color sorting with Cimbria’s highly advanced color sorting technology that can handle even the most complex applications without sacrificing speed.

-

Cimbria SEA.XL Optical Sorter

.png)

-

Cimbria SEA.IQ PLUS Optical Sorter

-

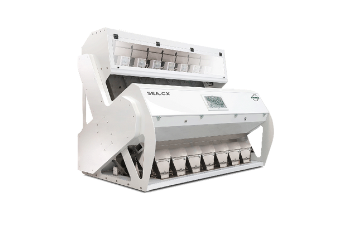

Cimbria SEA.CX Optical Sorter

-

Cimbria SEA.TN Color Sorter

-

Cimbria SEA.HY Color Sorter

.png)

Cimbria SEA.XL Optical Sorter

Whether you’re sorting seeds, grains, pulses, or specialty materials, the SEA.XL delivers industry-leading accuracy and efficiency—helping you maximize yield, protect product quality, and reduce waste.

Cimbria SEA.XL Optical Sorter Features

- BRAIN AI Software

Learns and adapts in real time, making intelligent sorting decisions with minimal operator input and optimized consistency. - Wide Chute and High-Capacity Design

Engineered for large-scale operations, with wide-frame sorting and adjustable chute configurations to support high throughput without sacrificing accuracy. - Intuitive Touchscreen Interface

User-friendly controls and diagnostics make it easy to configure recipes, monitor performance, and access critical data. - Real-Time Self-Calibration

Ensures stable performance throughout extended runs, automatically adjusting for ambient conditions and product variability. - Remote Connectivity and Smart Diagnostics

Stay connected with remote monitoring, support, and performance reporting to minimize downtime and optimize maintenance. - Modular Construction

Flexible design that supports future upgrades and easy integration into new or existing processing lines.

Cimbria SEA.XL Optical Sorter Benefits

- Maximize Product Recovery

Capture more high-quality material with fewer false rejects—even in challenging conditions. - Improve Throughput Without Sacrificing Accuracy

Handle large volumes without compromise, thanks to high-capacity chutes and lightning-fast processors. - Reduce Downtime and Operator Intervention

AI-powered decision-making means fewer manual adjustments and smarter self-learning for evolving materials. - Enhance Yield and Product Value

Achieve consistently high purity and grading standards to protect brand integrity and drive profitability. - Lower Operating Costs Over Time

Efficient processing, reduced waste, and improved sorting accuracy all contribute to long-term cost savings.

Material Types

- Grains: Wheat, corn, rice, barley, rye, and oats

- Seeds: Sunflower, soybeans, canola, grass seed, and vegetable seeds

- Pulses & Legumes: Lentils, peas, chickpeas, and beans

- Nuts: Almonds, peanuts, walnuts, and pistachios

- Specialty Crops: Coffee, cocoa, spices, and dehydrated vegetables

- Industrial Materials: Plastics, minerals, glass cullet, and non-food granulates

Cimbria SEA.IQ PLUS Optical Sorter

The IQ+ color sorter is specifically designed to meet your exact needs, provide unmatched precision of micro sized foreign bodies and defects for any market you are in. The all-new optical system features a set of cameras with the combination of RGB – NIR – SWIR camera technology give the highest amount of visibility even when separating foreign materials that are the same color as your desired output material. This advanced camera technology paired with high speed processors reduce false rejects and concentrate reject streams to make the SEA.IQ PLUS the top color sorting solution for your business.

SEA.IQ PLUS Color Sorter Features

- Full-Color RGB Cameras with Integrated Double-Frequency NIR

- Multiple vision packages with SWIR/InGaAs or UV

- SWIR (Short-Wave Infrared) InGaAs cameras using multiple frequency technology separate defects that cannot be visually detected—such as unhulled grains or shells

- NIR cameras excel at separating foreign materials from good products with similar colors like stick, stone, and plastic

- Vibratory feeding system

- Rapid-firing ejectors

- High capacity feeding chutes

- From 1-6 chutes with resort options

- Up to 96 ejectors per chute to help concentrate rejects

- AI technology to efficiently identify rejects

SEA.IQ PLUS Color Sorter Benefits

The SEA.IQ PLUS optical sorter is the most advanced vision-based sorter on the market uses multiple camera technologies, including a full-color vision system as well as NIR and InGaAs technologies. It can handle the most challenging applications for your business.

Cimbria BRAIN™ Intelligent Software

The SEA.IQ PLUS is powered by Cimbria’s proprietary BRAIN™ algorithm software, designed for intuitive operation and quick setup. This advanced platform allows users to rapidly fine-tune machine settings for optimal performance with minimal training—ensuring a seamless, user-friendly experience without compromising on precision.

Material Types

- Grains

- Seeds

- Pulses

- Coffee

- Nuts

- Plastics

- Metals

- Recycling

- Corks

Cimbria SEA.CX Optical Sorter

The SEA.CX optical sorter is the most advanced vision-based sorter on the market, proven excellent for sorting seeds, dry beans, peas, lentils, and edible grains. The advanced CMOS cameras in its full-color vision system combined with NIR and InGaAs technology, allow the SEA.CX color sorter to see what others can't, separating the finest defects. Optional UV upgrade removes toxins and diseases.

SEA.CX Color Sorter Features

- Full-Color RGB Cameras

- NIR and InGaAs Cameras

- NIR cameras excel at separating foreign materials from good products with similar colors like stick, stone, and plastic

- InGaAs cameras separate defects which cannot be visually detected like unhulled grains or shells

- Dedicated cameras for each chute provide the highest resolution Imaging

- Saved Recipes Store Sorting Parameters

- Control for Defect Size

- Sort by Shape

- Rapid-Firing Ejectors

- High-Capacity Feeding Chutes

SEA.CX Color Sorter Benefits

The SEA.CX optical sorter uses multiple camera technologies, including a full-color vision system as well as NIR and InGaAs technologies making it the most advanced vision-based sorter on the market, ready to handle the most challenging color sorting applications.

Material Types

- Grains

- Cereals

- Seeds

- Pulses

- Coffee

- Nuts

- Plastics

- Metals

Cimbria SEA.TN Color Sorter

SEA.TN Color Sorter Features

- Full-Color RGB Cameras

- NIR and InGaAs Cameras

- NIR cameras excel at separating foreign materials from good products with similar colors like stick, stone, and plastic

- InGaAs cameras separate defects which cannot be visually detected like unhulled grains or shells

- Saved Recipes Store Sorting Parameters

- Rapid-Firing Ejectors

- High-Capacity Feeding Chutes

- 1-7 chutes available to meet any production capacity needs

SEA.TN Color Sorter Benefits

The SEA.TN optical sorter utilizing true Full-Color RGB cameras can detect and separate the smallest color or shade differences in almost any bulk commodity to ensure the strictest food hygiene and health requirements of finished products are met.

Material Types

- Grains

- Cereals

- Seeds

- Pulses

- Coffee

- Nuts

- Plastics

- Metals

Video

Cimbria SEA.HY Color Sorter

The nut processing and confectionery industry are reliant on equipment that can effectively remove all foreign materials from their final products. Cimbria SEA.HY hyperspectral sorting technology guarantees the highest quality control at the end of the production line, particularly for high-value products such as hazelnuts, pistachios, almonds, and cocoa beans.

SEA.HY Color Sorter Features

- Advanced Near-Infrared Technology

- EXAGON Software

- The new EXAGON software allows the user to set the defect size and can recognize up to 16 families of defects.

- 22-Inch Color Touch Screen Display

- Rapid-Firing Ejectors

- Feeding system can be separated into two sections to handle different sizes of materials

SEA.HY Color Sorter Benefits

The SEA.HY electronic sorter is equipped with Hyper Spectral Near-Infrared Sensors able to recognize defective products according to their chemical nature, therefore removing defects of the same color as a good product. Its reliable performance ensures maximum color sorting productivity and collection of rejects. This machine is an ideal color sorting solution for elements sized from 2mm to 30mm.

Material Types

- Hazelnuts

- Pistachios

- Almonds

- Cocoa Beans

- Walnuts

- Other Nuts

- Plastic flakes and pellets

![]()

Related Videos

View Playlist

Cimbria SEA Color Sorter Overview

Cimbria SEA Color sorters offer leading edge sorting capability and flexibility to meet your operational needs. In this video, we look at a TN 3 machine.

Watch on YouTube →

Cimbria SEA Hopper and Flow Options

With any of our Cimbira color sorters, we are able to customize the congiuration to meet your needs. The SEA's are configured with each chute having their own feeder and camera, meaning each chute can handle a separate pass or product simultaneously, while managing flow levels and through put for seemless operation.

Watch on YouTube →

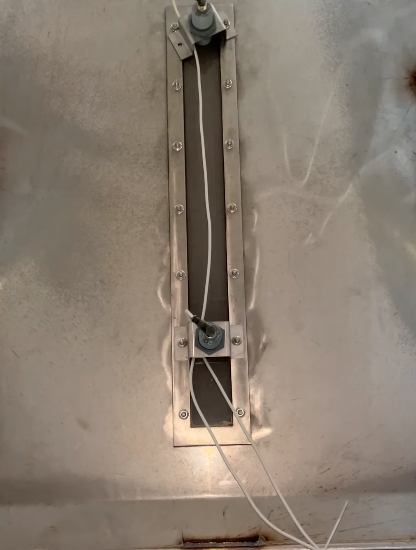

Cimbria SEA Maintenance

As with any processing equipment and system, maintenance and access is critical to longevity. In this video, we review the access and maintenance points of the sorter.

Watch on YouTube →Resources

Seed treatment is a cornerstone of modern agriculture. It enhances crop productivity, ensuring farmers get the most out of every seed. By leveraging...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.