Agricultural plants begin life as fragile seeds that must be handled with meticulous care. Each step of the seed conditioning process is critical to...

Precision Cleaners for Seed, Grains, and Edible Products

Ensure the quality of your products with Cimbria’s top-of-the-line precision screen cleaner.

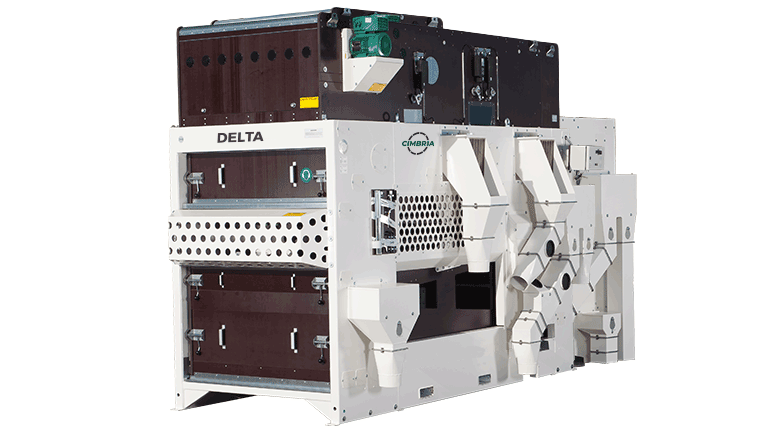

Cimbria Delta Super-Fine Cleaner 100 Series

Cimbria's 100 Series of Super-Fine screen cleaners are designed for high-quality cleaning of seeds, malting barley legumes, grains, and grass seeds. The unique airlift fan makes the 100 series Ideal for the most challenging separations.

Cimbria Delta Super-Fine Cleaner 100 Series Features

- Shaker feeder

- Airlifting fan

- Pre and after-suction

- Recipe driven from electronic control system

- 9" color touch screen operator Interface

- Fully customizable screen flow options

- Capacity up to 25 tons per hour

Cimbria Delta Pre-Cleaner 100 Series Features

The Delta 100 Series has the most advanced air system on the market resulting in a better product exiting this machine. This series is suitable for cleaning of all kinds of grain and seed. Ideal for difficult separations.

Material Types

- Barley

- Clover

- Corn

- Dry Beans

- Green Coffee

- Oats

- Peas

- Rapeseed

- Paddy & White Rice

- Rye

- Rye Grass

- Sorghum

- Soybeans

- Sunflower

- Vegetable Seeds

- Wheat

Cimbria Delta Fine Cleaner 110 Series

The Delta Fine Cleaner 110 Series is designed for fine cleaning of grain and seed. Very similar in design to the Delta 100 series, however, it does not include air lifting fans.

Cimbria Delta Fine Cleaner 110 Series Features

- Shaker feeder

- Pre and after-suction

- Recipe driven from electronic control system

- 9" color touch screen operator Interface

- Fully customizable screen flow options

- Capacity up to 40 tons per hour

Cimbria Delta Fine Cleaner 110 Series Benefits

The Delta Fine Cleaner 110 Series are extremely versatile machines due to their combination of flexible screen flows and standard features. This makes the Cimbria 110 cleaner series well suited for both fine cleaning and Industrial cleaning of many products.

Material Types

- Barley

- Clover

- Corn

- Dry Beans

- Grass Seed

- Green Coffee

- Oats

- Paddy & White Rice

- Peas

- Peanuts

- Rapeseed

- Rye

- Sorghum

- Soybeans

- Vegetable Seeds

- Wheat

Let's Talk

We want to help you find the right fit for your next precision cleaning system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Contact UsRelated Videos

View Playlist

Cimbria Delta Super Cleaner Overview

The Cimbria Delta super cleaner is the ultimate in seed and grain cleaning, here's an overview of the machine.

Watch on YouTube →

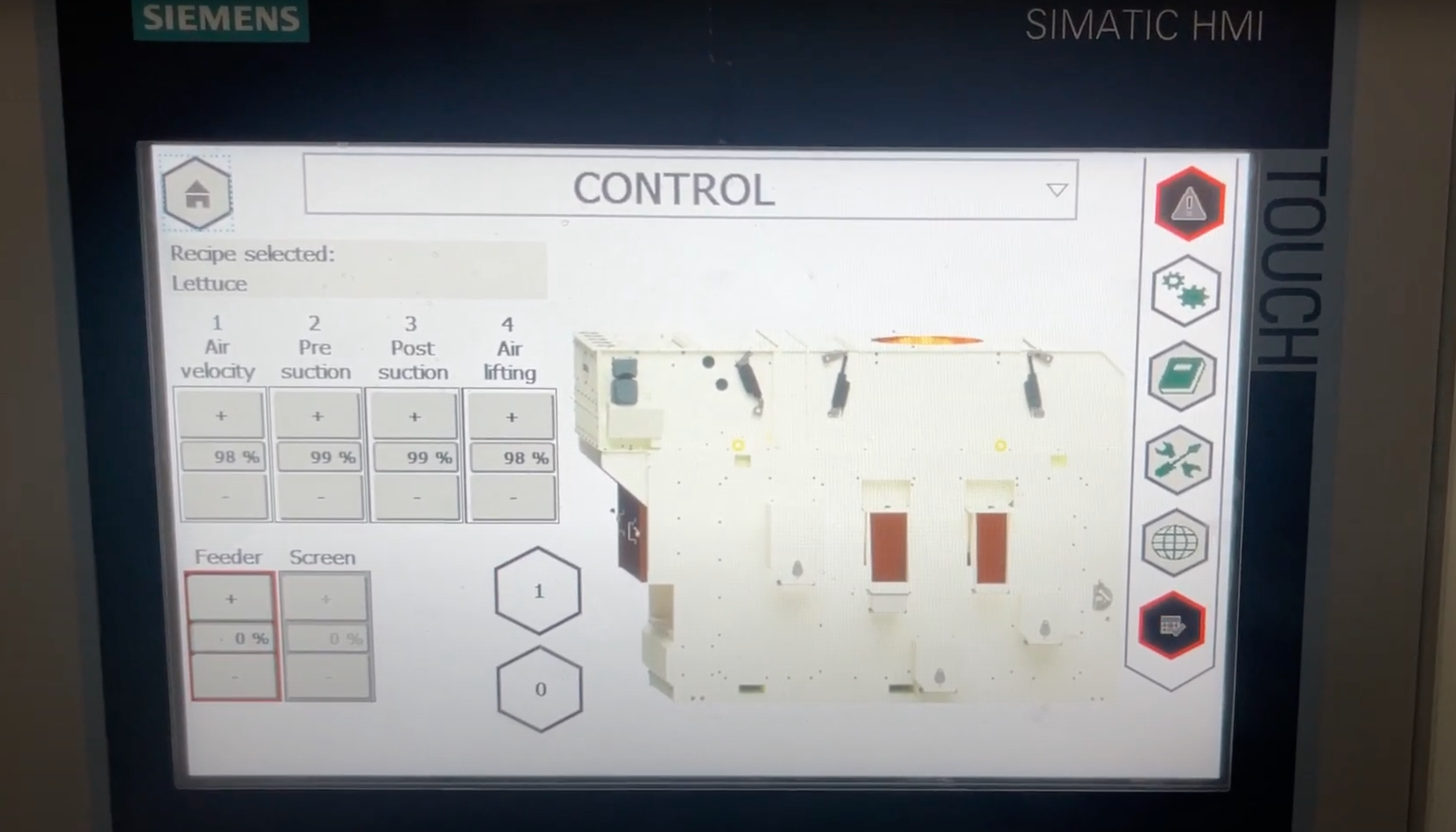

Cimbria Delta HMI Control Overview

Cimbria now offers a HMI control for the automated, recipe based operation of it's seed processing equipment. Here's a quick look at the functionality of that interface.

Watch on YouTube →

Cimbria Delta Ball Racks Tips

Ball boxes are critical to the proper operation of the screen section of a grain cleaner. Here's the proper way to install and fill them with cleaner balls.

Watch on YouTube →Resources

Seed treatment is a cornerstone of modern agriculture. It enhances crop productivity, ensuring farmers get the most out of every seed. By leveraging...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.