Project Background

Challenged by the local landscape and running the project on an operational site, Bratney's project management team worked closely with the customer operations and management to ensure their existing operations could run safely and uninterrupted. Due to the local site conditions, extensive site preparation was required including:

-

Demolition of an existing building

-

Remediation of contaminated soils

-

Local blasting of buried rock shelves

-

Construction of an underground stormwater retention system

-

Specialized building foundations with rock anchors.

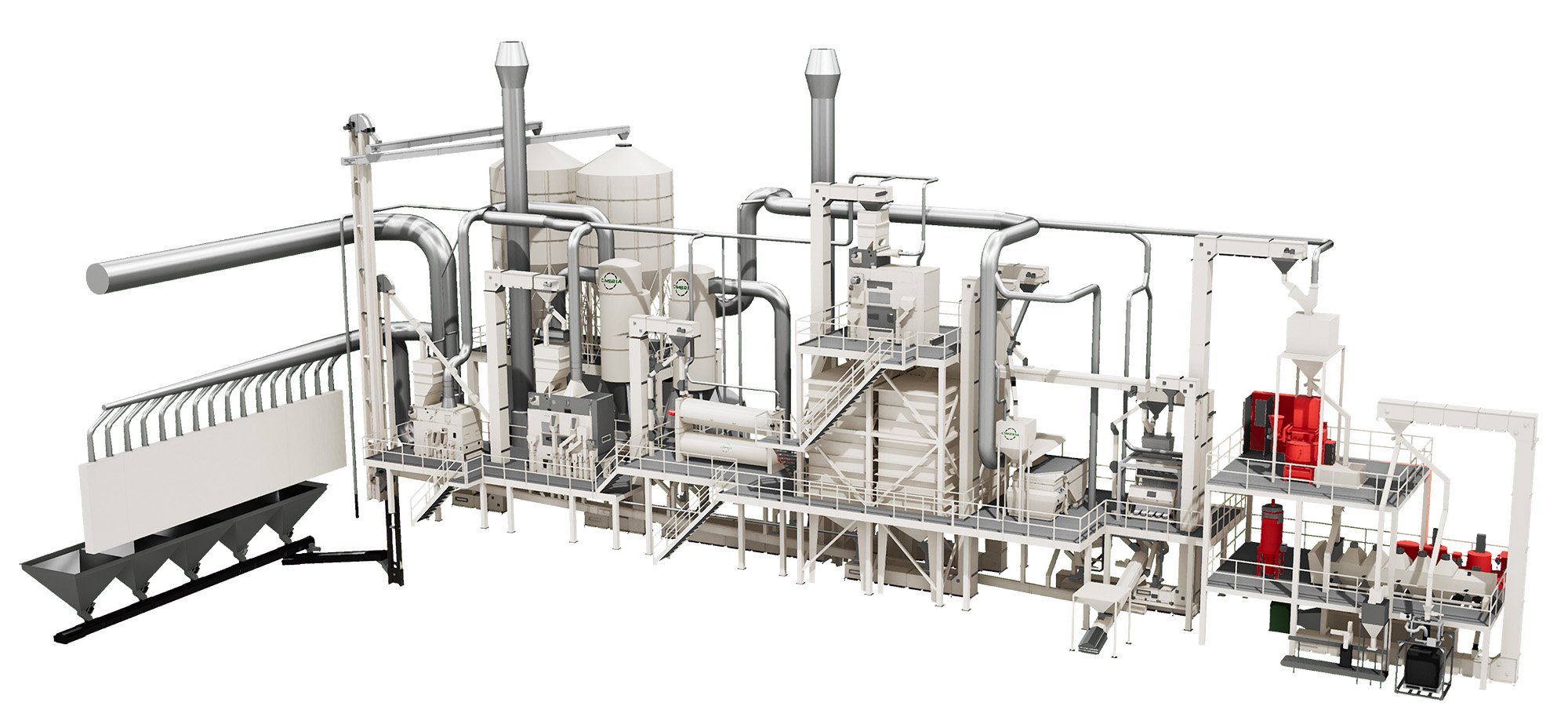

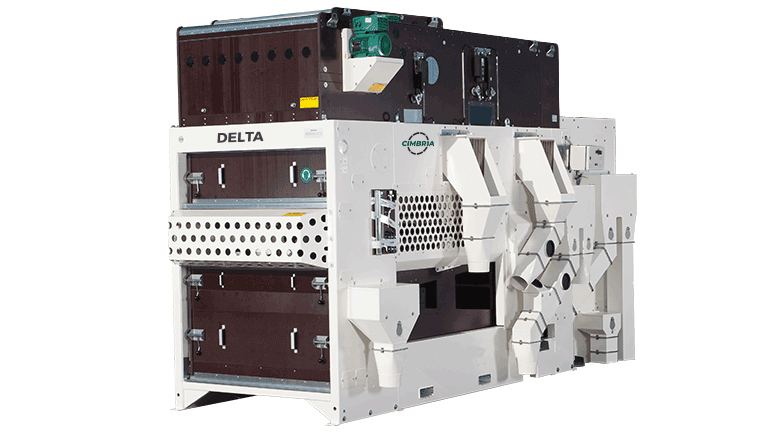

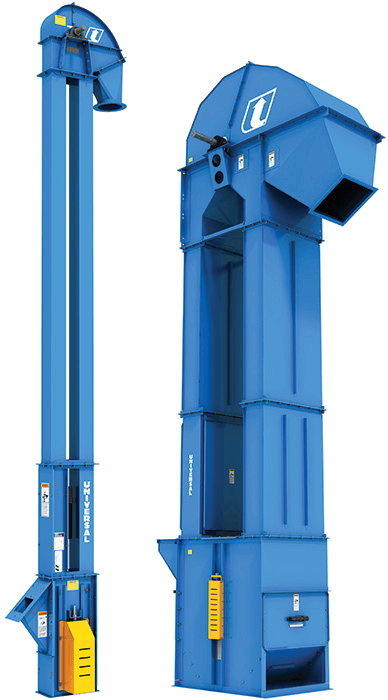

Another interesting aspect of the project was an innovative process flow. The customer frequently cleans different varieties of alfalfa seeds, and consequently can't have any cross-contamination. Bratney designed two mirrored seed cleaning lines, each with a capacity of 5,000 lbs. per hour, allowing the customer flexibility to run two products independently or one product at twice the capacity.

In addition to the 10,000 sq. ft. processing tower, Bratney also designed and constructed a 100,000 sq. ft. storage warehouse and a separate 8,000 sq. ft. office space.

/Alfalfa%20Seed%20Conditioning%20(Images)/bratneyseedprocessdesign_84E4F16950BF1.jpg)