Project Background

Millborn Seeds in Brookings, South Dakota was at a crossroads in their business. Either maintain the status quo and continue to run a successful business or take advantage of the growing specialty seed market and invest in new processing capability to advance their position as a leader in the specialty seed and cover crop markets.

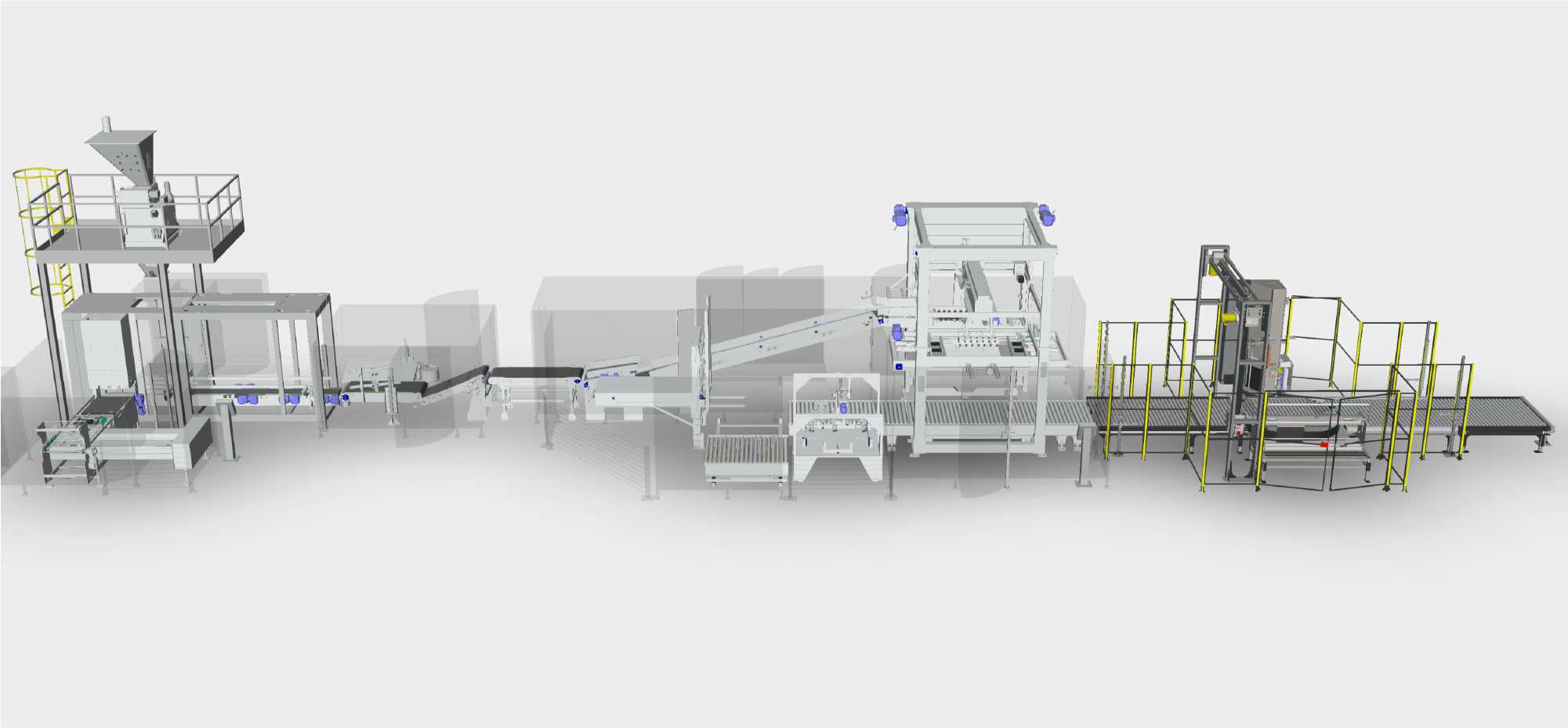

Taking the growth mindset, Millborn Seeds turned to Bratney for help navigating the options available for a new seed blending and packaging process that ensured gentle handling, no cross-contamination, speed and efficiency. Bratney’s project development team worked with Millborn to review process flow options, equipment solutions, and the associated capital costs to ensure the final scope of work was an ideal match for Millborn’s vision and goals for the project.