Project Background

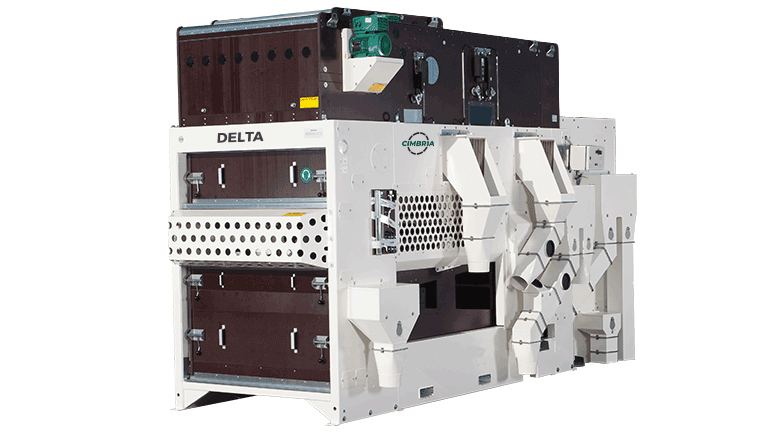

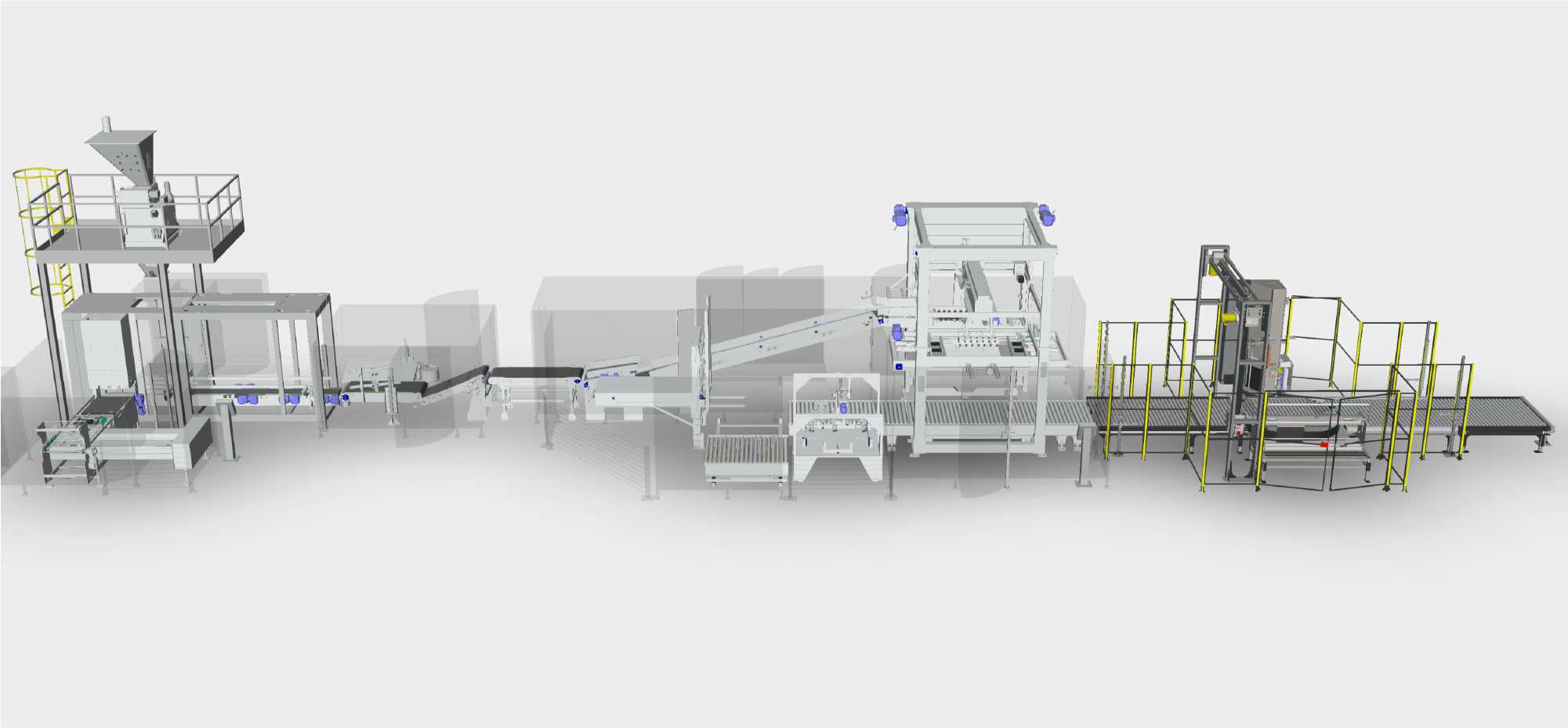

Bratney’s process engineers worked side-by-side with the owner to develop a conditioning line that segregated different soybean varieties to prevent cross contamination. Careful consideration was given to proper access points for each bin, elevator and piece of soybean conditioning equipment ensuring total clean out between varieties.

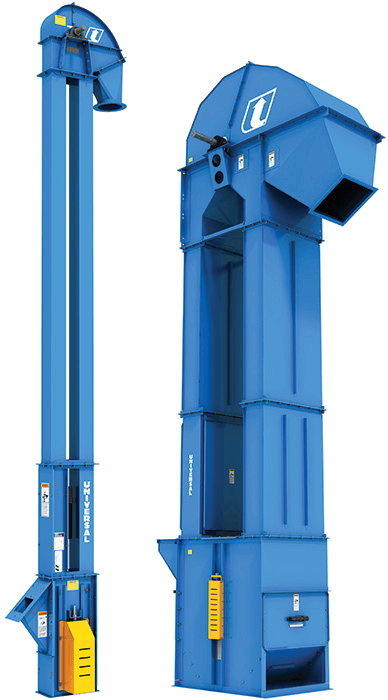

Being a food grade plant, both gentle product handling and specific sampling points to meet FDA and FGIS standards were critical to the success of the project. Bratney used a combination of let down ladders, continuous cup elevators and a thoughtful process flow that minimized the handling points to ensure a high-quality and safe finished product.

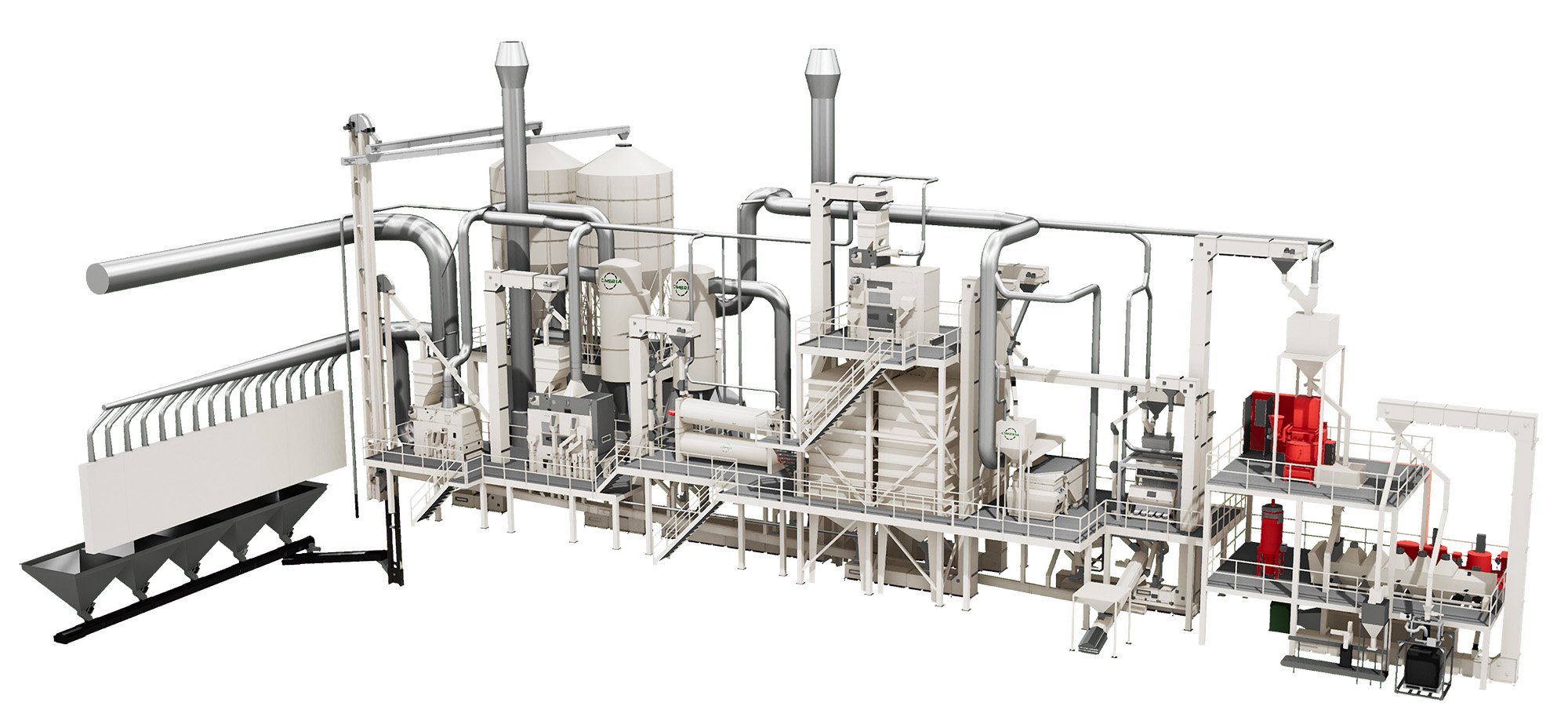

The plant includes a 4,000 bushel per hour enclosed receiving lane, 400 bushel per hour processing tower, packaging building, warehouse, and offices. Despite challenging weather conditions throughout winter and an unusually wet spring, Bratney’s millwright team delivered the plant on time to meet customer’s production plan.

/Edible%20Bean%20Processing%20(Images)/soybeancleaningseparatingprocess_9695AF16E054A.jpg)