Project Background

Ag Com ultimately selected Bratney for the project being a "one stop shop" for the process design, milling equipment, construction and millwright services required to deliver the facility in turn-key fashion - allowing them to continue operating their existing flour mill, soybean processing plant and seed business during construction of the new project.

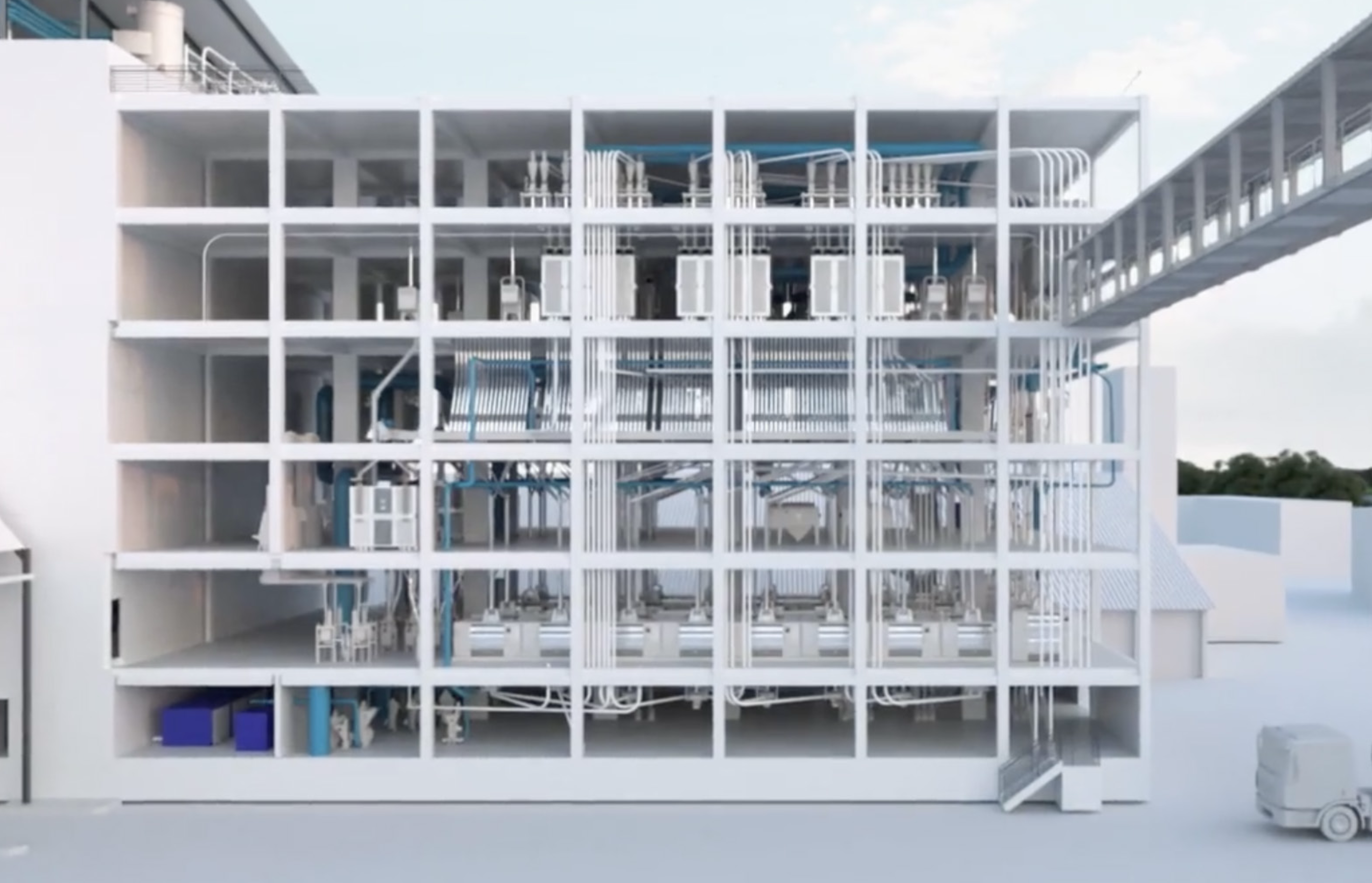

The new mill produces 2,500 cwt/day and included a forward-thinking layout to easily accommodate future expansion to 5,000 cwt/day. It’s sanitary design leaves prospective customers highly confident in the quality and cleanliness of their flour.

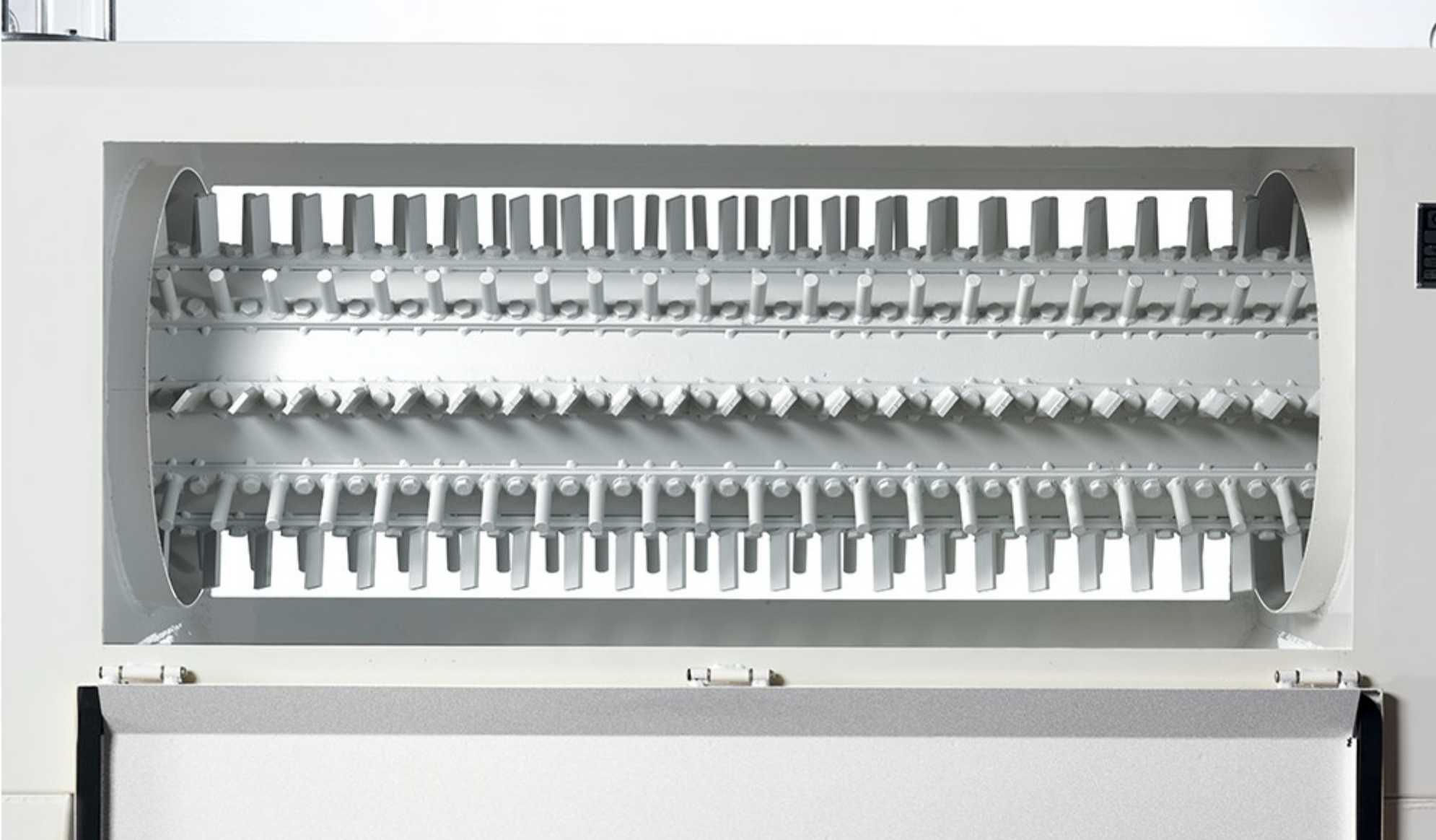

At the time of construction, the new will was the first in the United States to take advantage of Omas’ energy saving Leonardo roll stands. Omas’ patented Kinetic Energy Recovery System (KERS) provided game changing energy savings for Ag Com, allowing them to do the project within the very limited electrical supply to their site.

Project Details

-

Bratney completed initial site work and grading layouts to ready green-field site for construction

-

5 story pre-cast concrete building with concrete floors

- 2,500 cwt/day flour milled, planned for future expansion to 5,000 cwt/day

- 810,000 lbs. finished flour storage

- pneumatic finished product transfer

- enclosed bulk loadout building

Equipment Solutions

-

Omas Leonardo roll stands

-

Omas Galileo plansifters

-

Omas Michelangelo purifiers

-

Omas Raffaello bran finishers

-

Omas Mantegna drum detacher

-

Jet filters

-

Air make-up system

-

Drag conveyors

-

Omas screw conveyors

- Pneumatic conveyors