Project Background

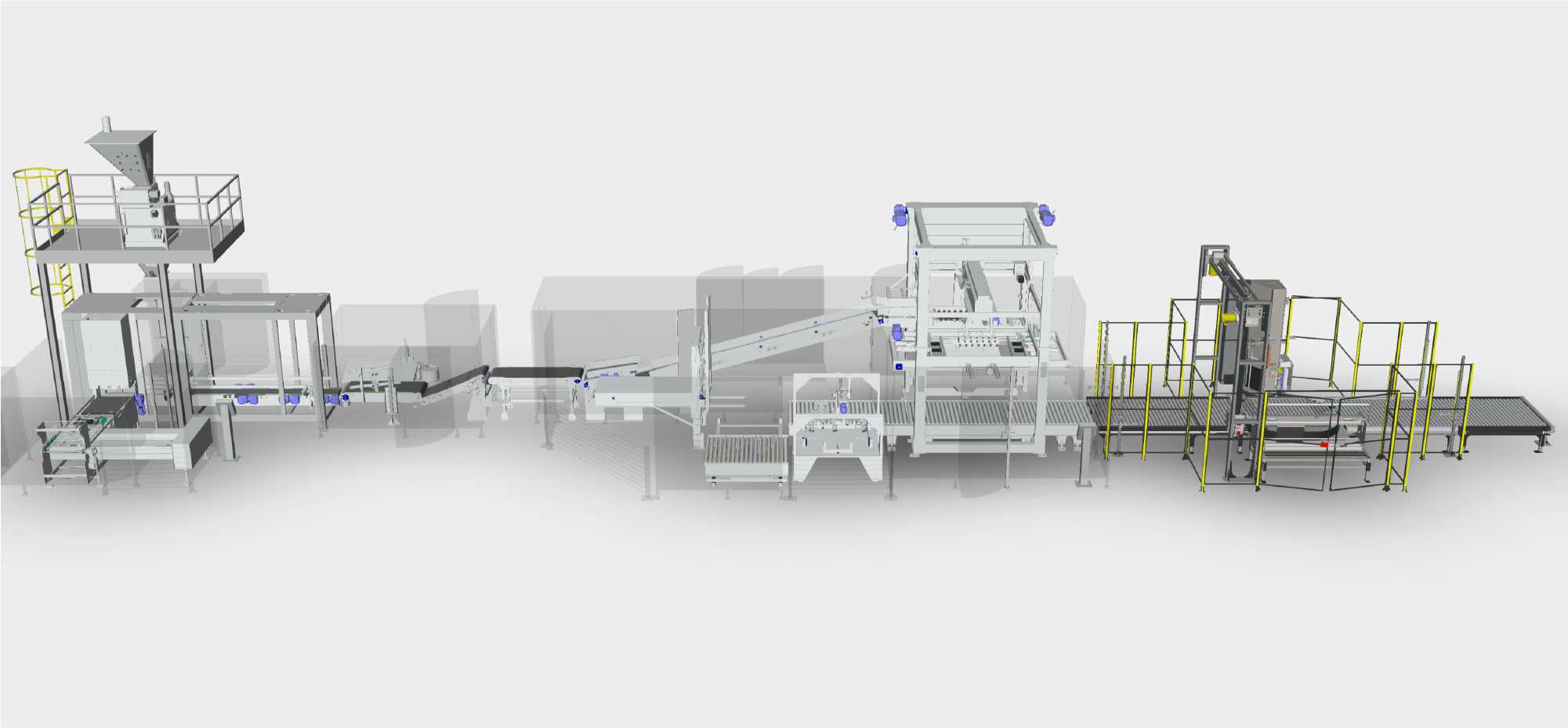

Bratney’s process design team started with the end in mind, developing an extremely flexible process flow that converts baled whole cone hops to pelleted hops. The plant was designed to handle an initial capacity of 3 tons per hour with the ability to expand it to 6 tons per hour. Specific attention was given to three critical areas particular to processing hops:

-

hops are not free flowing so extra steps were taken in the design and installation of the material handling equipment, transitions and spouting to eliminate hang up points and prevent bridging

-

the process flow was done to ensure easy access to the process equipment and conveyance and equipment features were added to aide cleanout as the resin in hops tends to build up on contact parts and must be cleaned

-

great care was taken to prevent and reduce the hops exposure to both heat and oxygen, two items that are detrimental to the overall quality of the pelletized hops