Project Background

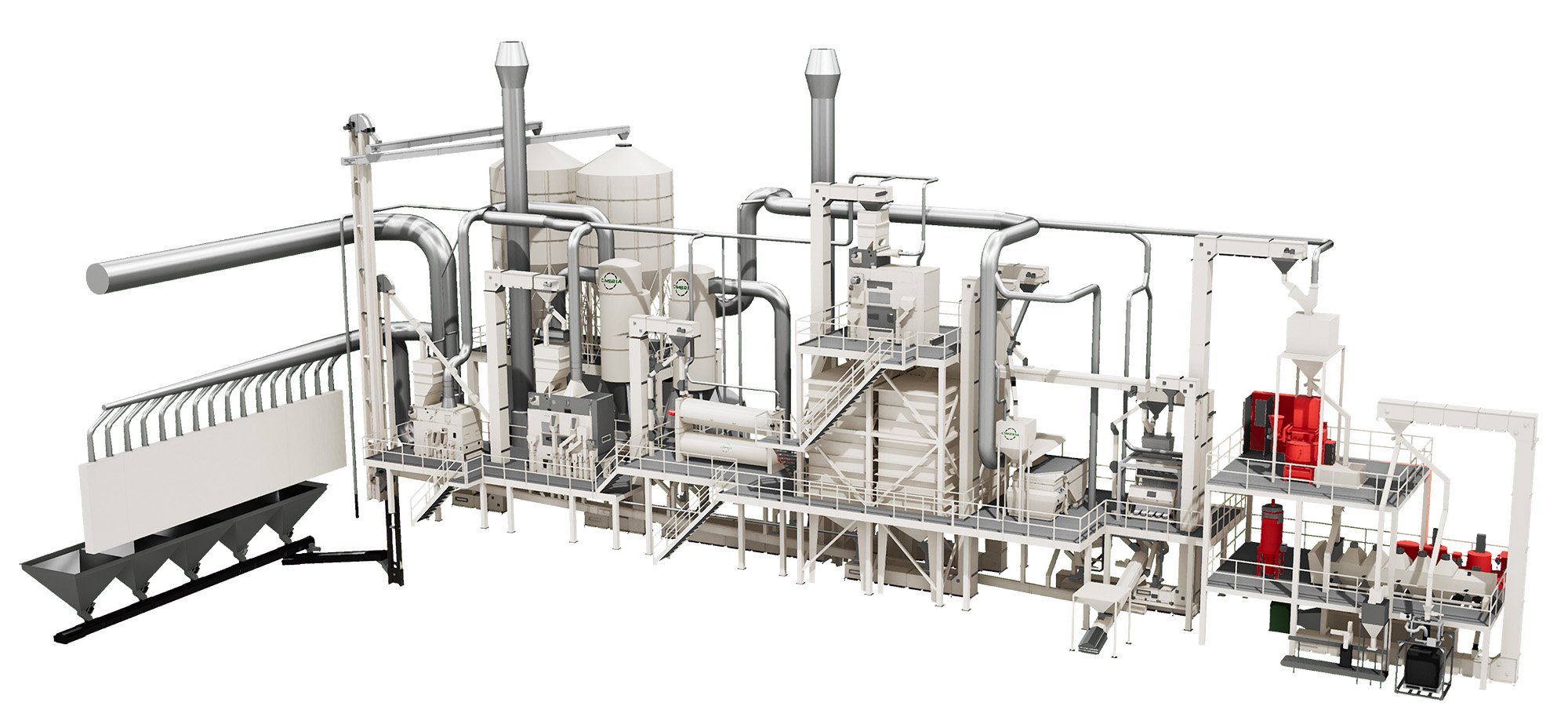

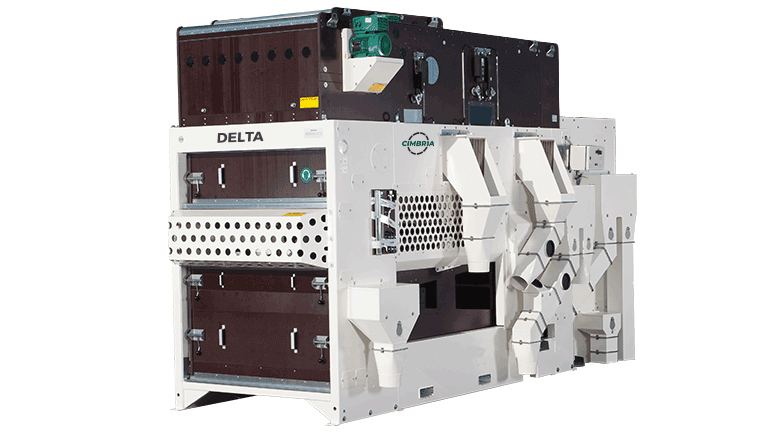

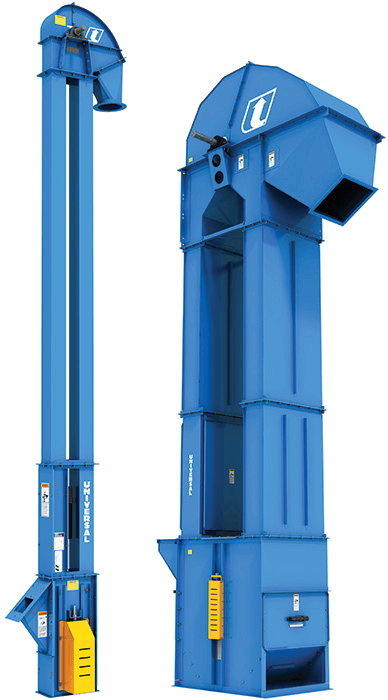

The project scope encompassed a comprehensive design and installation of various systems crucial to the seed processing operation, including material handling equipment, advanced cleaning and treating machinery, as well as solutions for finished product packaging and storage. This multifaceted approach was essential to ensure that every aspect of the seed processing line was efficiently integrated.

Bratney’s project team collaborated closely with the Richardson team throughout the entire process. This partnership was vital in ensuring that the new plant was not only tailored to fit seamlessly within their existing site but also optimized for high throughput. The design focused on creating an efficient workflow that minimized bottlenecks and maximized productivity.