Project Background

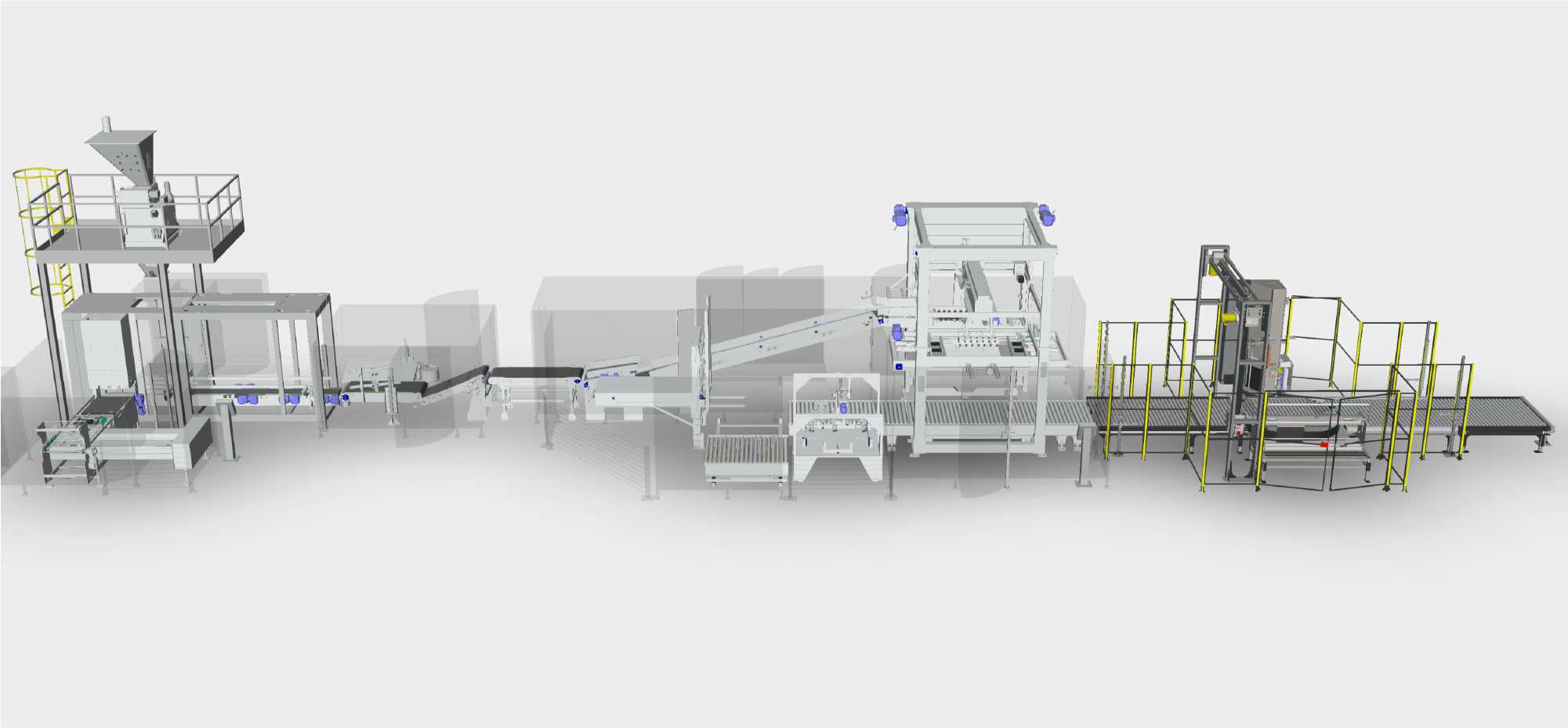

Chippewa Valley Bean, a processor of premium quality kidney beans had experienced incredible growth and needed to automate their packaging equipment alongside a warehouse expansion. After assessing options, they turned to Bratney to handle the project which included engineering and installing a new material handling system with a massive overhead conveyor bridge and automated bagging machines for fifty pound bags and supersacks ranging from 2,000 to 4,400 pounds.

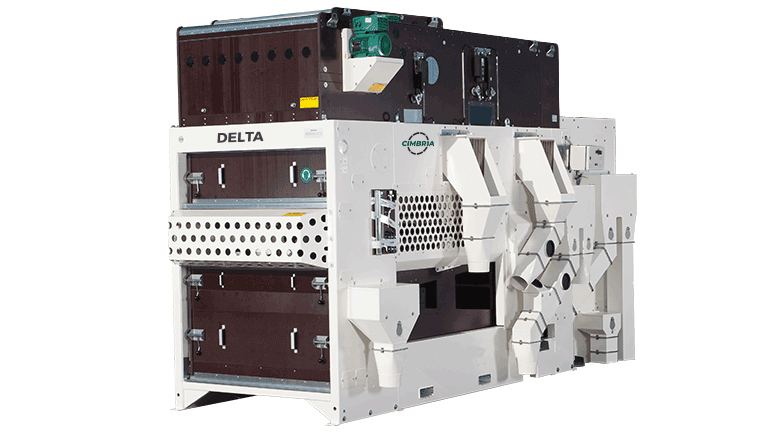

Bratney's process equipment expertise proved invaluable to their project as the engineering phase included a few rounds of potential equipment solutions to best match project goals and budget, including a few specialized machines that Chippewa Valley Bean was not aware of. To pull the whole project together Bratney's construction crews went arguably beyond the call of duty in order to deliver the project safely and on time despite some very challenging weather conditions from Wisconsin’s long, cold winter.

Bratney’s local territory manager, Keith Bos, and packaging equipment division worked with Chippewa Valley Bean to assess their process capacity, select the proper bagging scales and bagging machines and then fully automate their bag tagging process with an integrated print on demand tagging system. The team also worked with proprietary equipment partner Concetti to design the automated bagging machine with a unique feature on the empty bag magazine reliably pick and hang the porous poly woven bags used in the bean industry. The effort resulted in a highly efficient, fully automated bagging system for their 50 lb. bagging line.

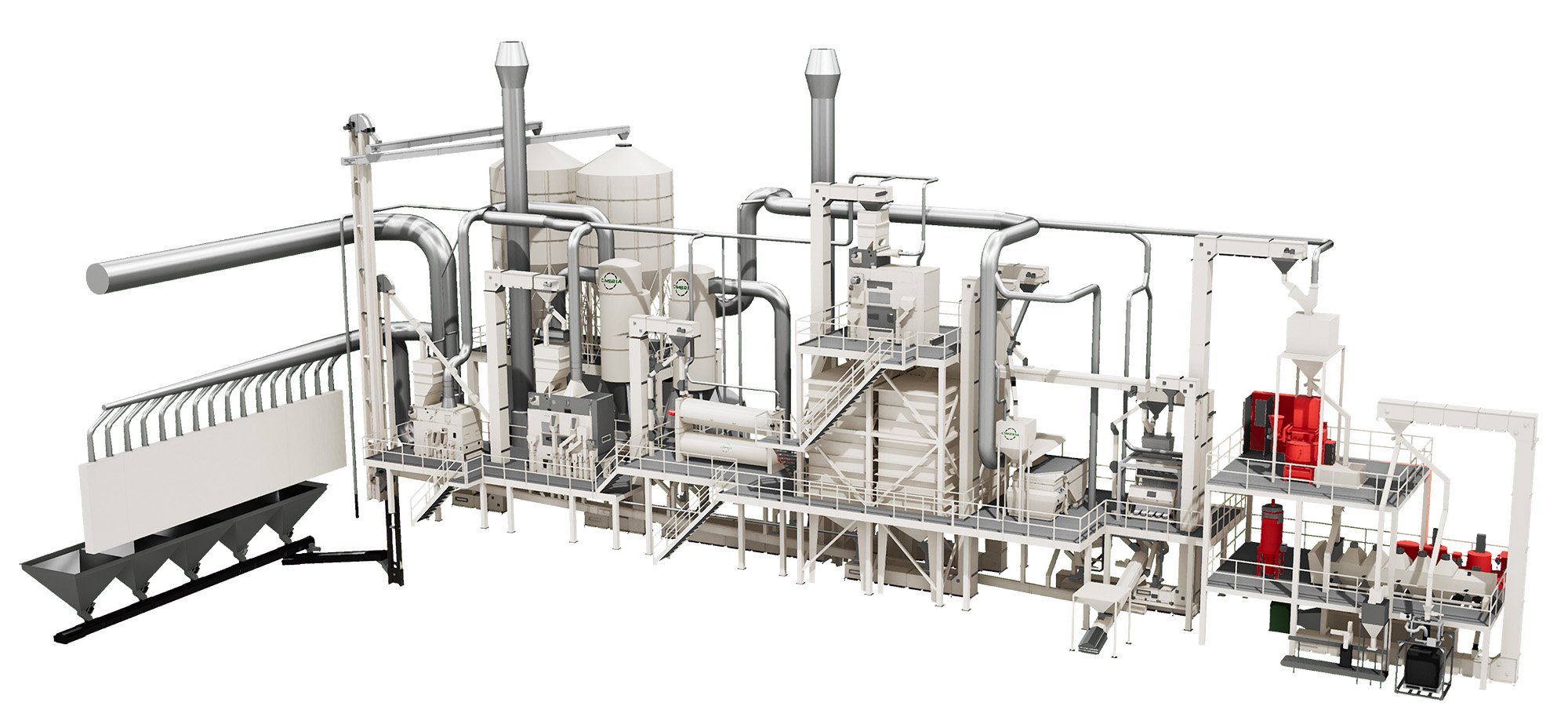

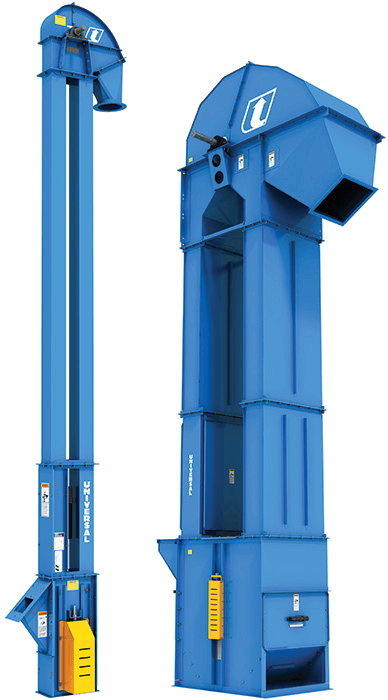

To deliver kidney beans from the conditioning building to the new supersack bagging system, Bratney's engineering and construction division designed and installed a 250-foot-long conveyor bridge from the cleaning line to the new warehouse. This conveyor bridge was designed with capacity to double in size to support the addition of another tote bagging system in the future.