Project Background

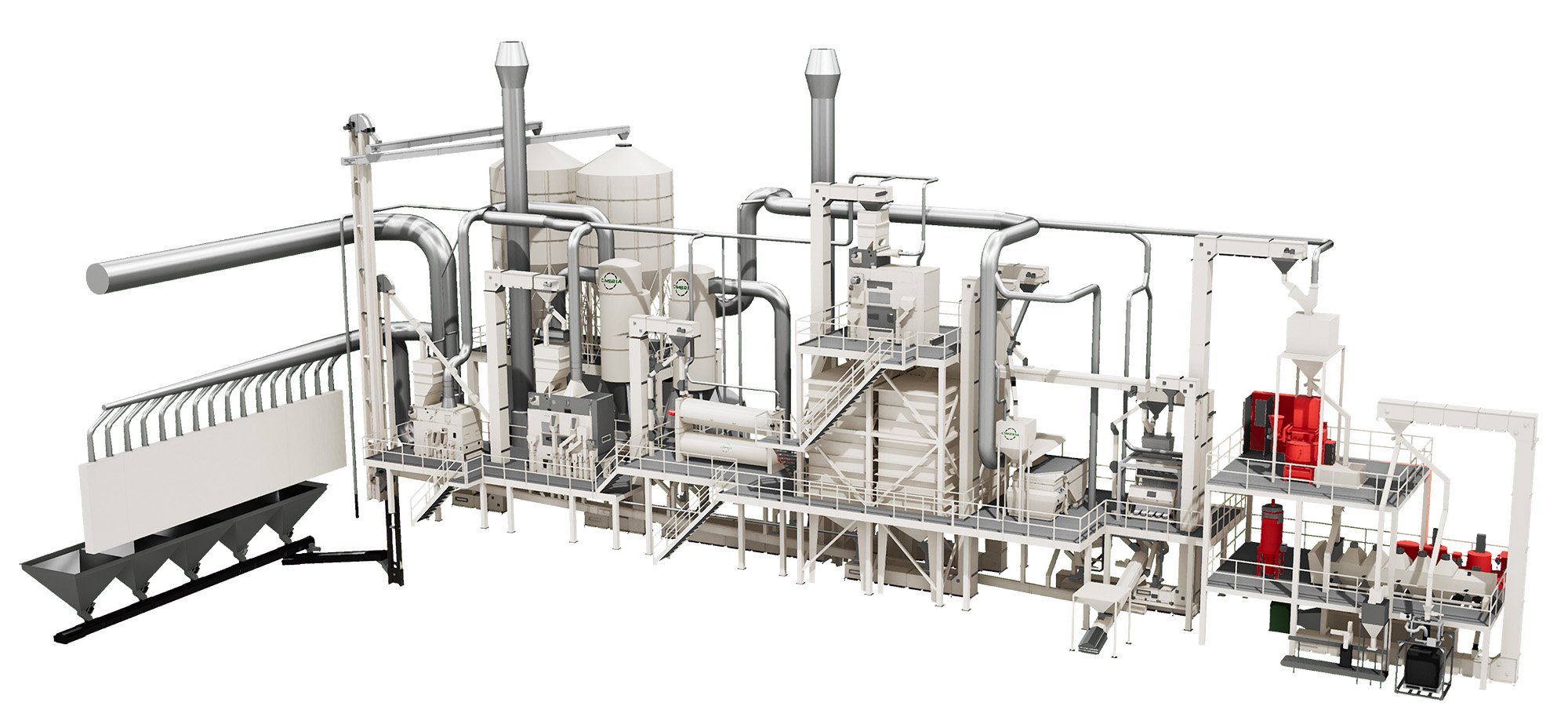

Through a collaborative effort between Bratney’s project development team and our client, an innovative process flow and plant design was conceived. From that point, Bratney design staff began detailed engineering to not only eliminate antiquated steps in the process, but to carefully place the equipment, structures and platforms in the most efficient manner providing for optimum performance and accessibility.

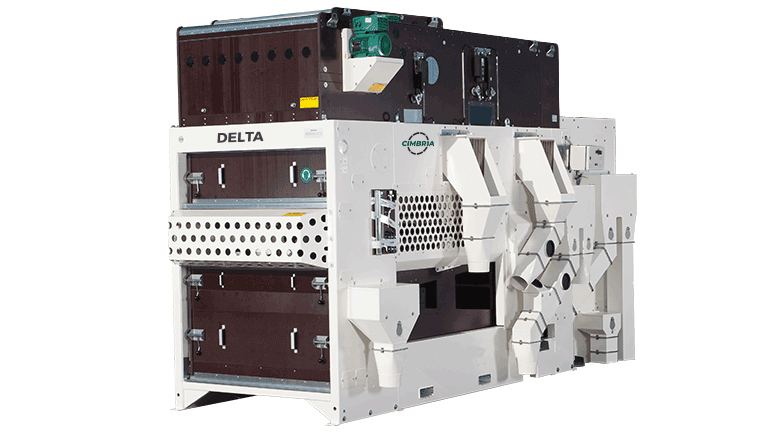

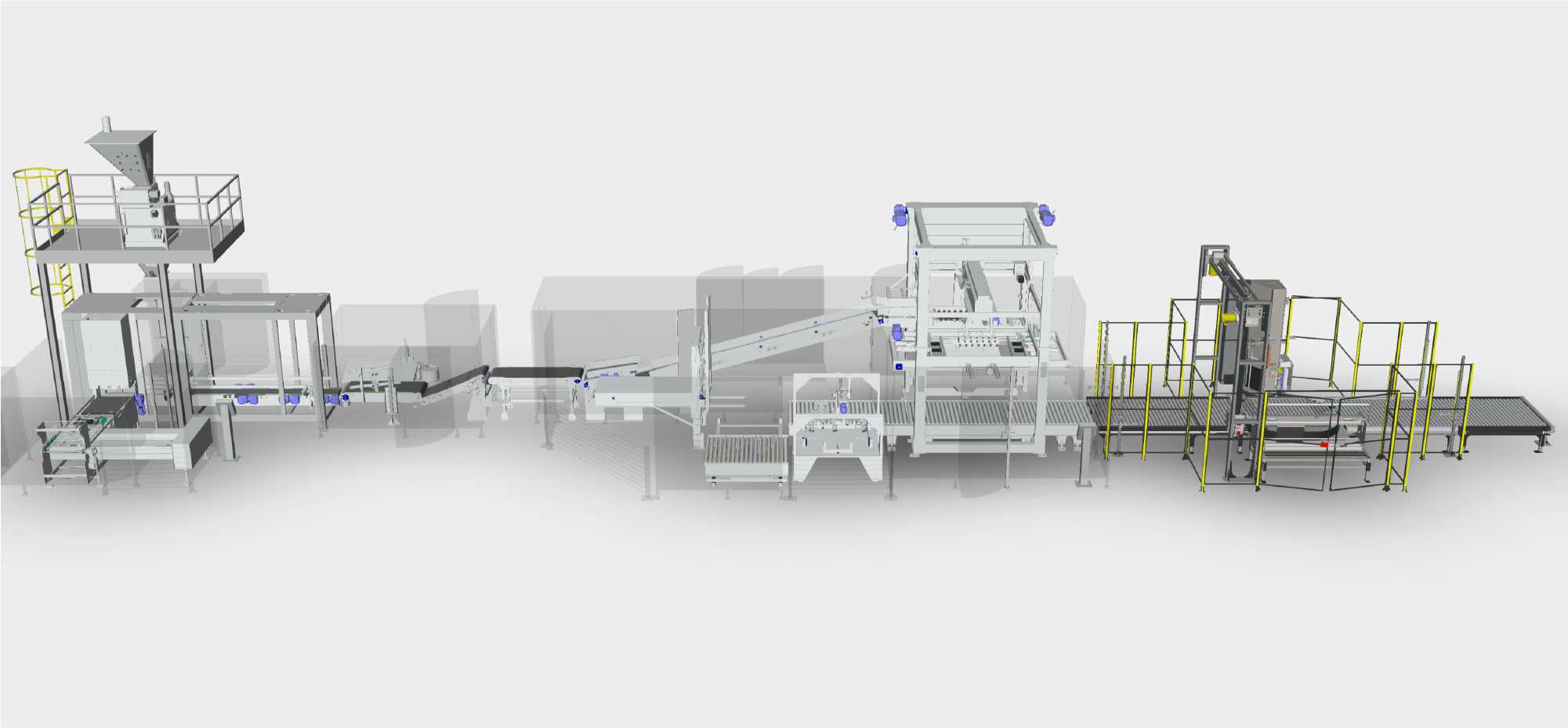

All of this was done being ever mindful of the client’s budget and their desire to incorporate the latest processing and packaging equipment from Cimbria and Concetti. This technology allowed them to beat the industry standard of 1-2% foreign material by nearly 2 full percentage points, producing 99.9% perfect popcorn.

The automated plant safely processes 42,000 lbs. / hour with only three operators. And, more importantly at a quality level not achievable without the advanced technology Bratney process engineers incorporated in the design.

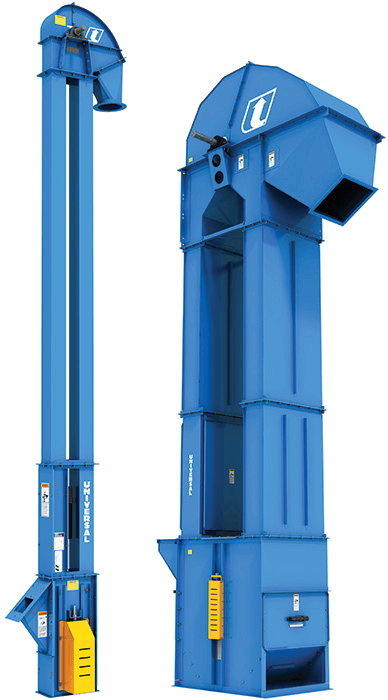

Food processing plants require not only a quality design, but attention to details. Bratney millwrights are experienced in the proper installation of conditioning equipment, material handling systems, storage systems, dust control systems and compressed air systems. Those skills combined with those of our start up and service technicians, allowed us to commission each system, train the plant operators and successfully bring this plant online.