Project Background

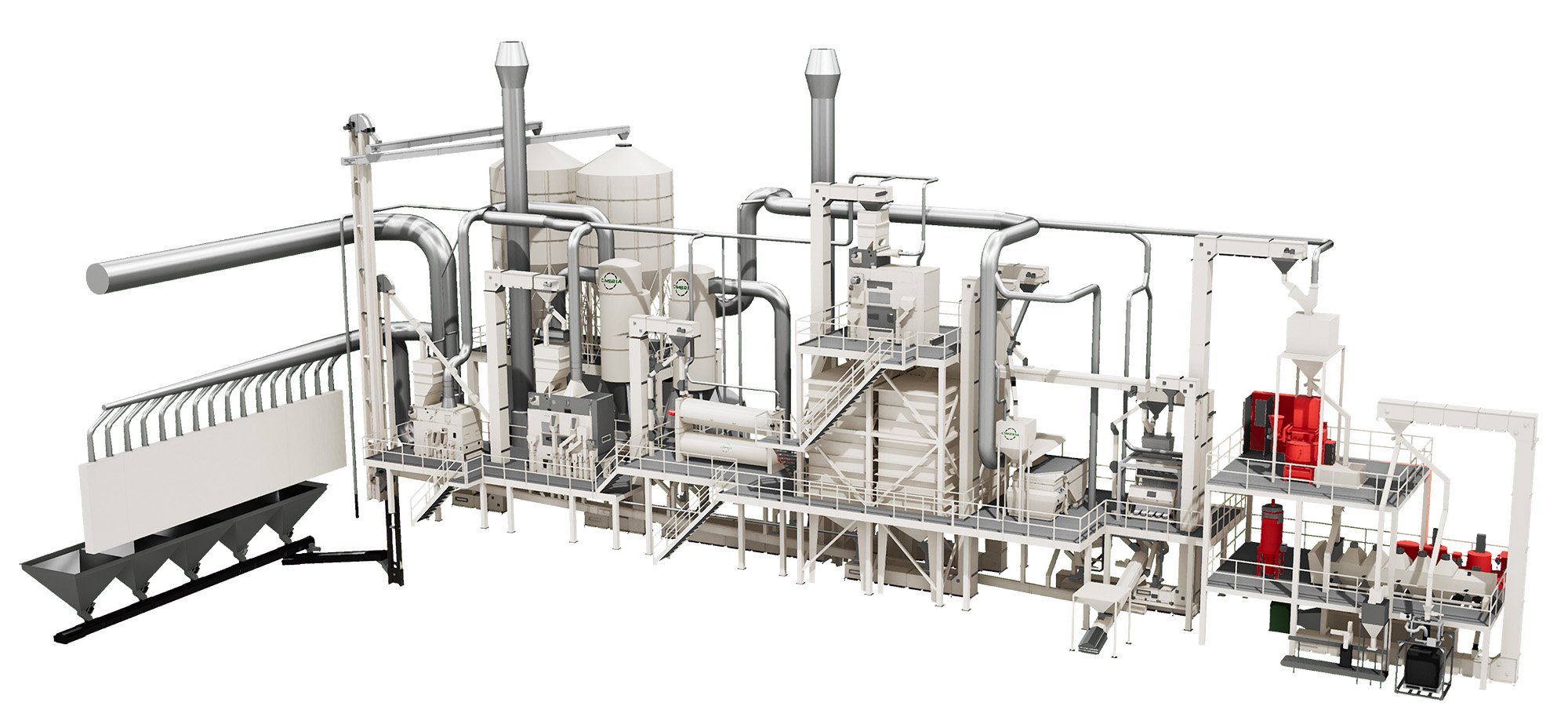

After listening to McKillip Seeds’ goals for the new soybean seed and wheat seed receiving and cleaning line, Bratney’s project team developed multiple process flows for the McKillip Seeds to consider. Ultimately it was decided that the most efficient and cost-effective way to reach the quality goals they had outlined were to move forward with the flow that eliminated the gravity tables and their high cost of operation.

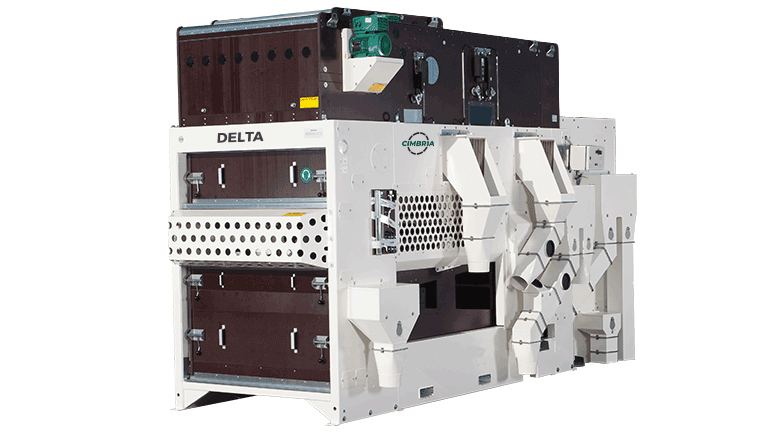

To ensure finished seed would deliver the quality associated with the McKillip brand, Bratney opted for a Cimbria Delta 106 screen cleaner and a SEA.CX, six lane optical sorter in the 500 bushels per hour cleaning line. While the building was contracted to a local building manufacturer, Bratney provided the design and engineering for the seed conditioning line, millwrights crews to install the equipment as well as guidance on the optimal building size to house the cleaning line.

/RP_00022-16%20copy-1440x960.jpg)