Project Background

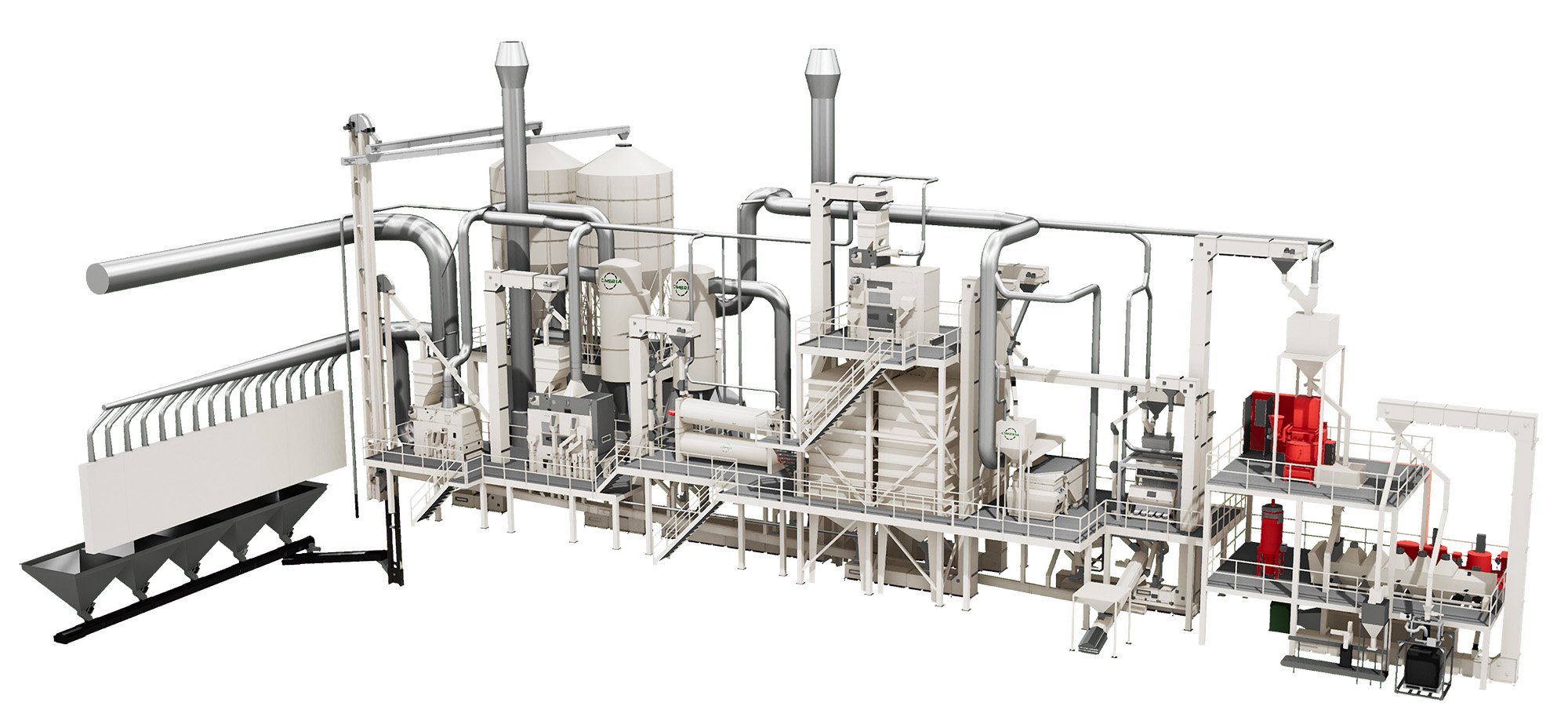

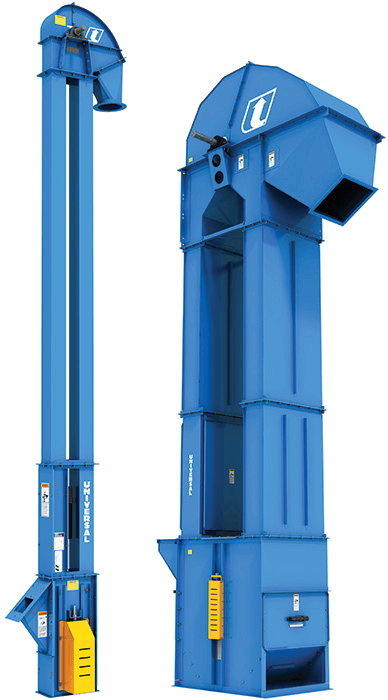

With flexibility and automation in mind, Bratney's process engineers developed a unique and automated process flow from receiving through conditioning. The receiving line handles either 42 cubic feet per hour or 600-1,600 pounds per hour depending on the seed species. A combination of pneumatic conveying, valving and spouting delivered the flexibility to convey each species of seed to the specific cleaning and conditioning equipment appropriate for that seed. An additional benefit of the flexible pneumatic conveyors was gently handling of the seed to protect and preserve it as it travels through the processing line. Bratney's designers took extra care to ensure access to equipment and material handling systems for easy cleanout between species.

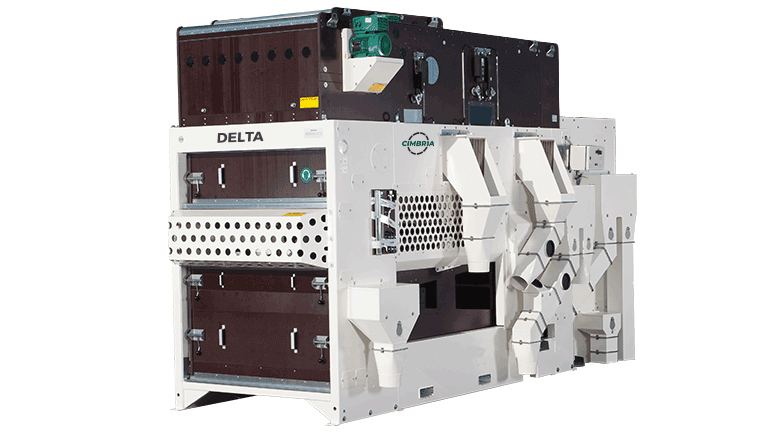

To deliver this high-quality seed cleaning line, Bratney engineers integrated equipment from select manufacturers around the globe including: Denmark, Austria, Italy, Japan, The Netherlands, Germany, USA and Canada. Project management was critical to the success of this project. Careful planning and frequent communication were paramount to finish the project within the 6-month construction window.

/Vegetable%20Seed%20Processing%20(Images)/cimbriagravitytablecolorsorter_12876CCAA1E92.jpg)