Understanding the Role of Screw Conveyors in Bulk Material Handling

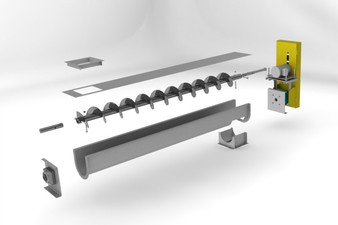

Screw conveyors, also known as auger conveyors, are used to efficiently transport dry bulk materials such as grains, flours, animal feed, fertilizers, and more. They work by rotating a screw within a trough, moving material simply and efficiently. Screw conveyors require little maintenance and provide a durable solution that can be used 24/7 for optimal productivity. As a result, they’re an essential tool for moving a wide variety of dry bulk products.

Types of Screw Conveyors

Screw conveyors have basic parts in common, but many of these come in many different variations, making this type of machine useful in a wide range of applications. Below are examples of common variations.

Trough Options

The trough is the channel through which material moves as it’s transported by the screw conveyor. It is covered to keep the material safe from contamination. Bulk material is fed into the trough through an inlet, which can be connected to other devices that control the flow into the trough through silos, bins, or other storage vessels. The trough can be aligned vertically, horizontally, or at an incline as needed to deposit material at its destination via one or more outlets.

Troughs can be tubular, U-shaped, or rectangular, and they may be constructed of different types of steel depending on the type of product to be moved. For example, abrasion-resistant rectangular steel troughs are best for moving abrasive materials, while U-shaped mild steel is most common and suitable for most applications. Tubular troughs provide added protection from contaminants and can operate at higher speeds and capacities. Troughs are available in a range of sizes to accommodate various capacities and flow rates.

Flight Options

The flight is the blade part of the screw, which runs helically along the inside of the trough. In most cases, it is wrapped around a central shaft. However, shaftless varieties, which are better able to move sticky, wet, viscous, or stringy materials, are also available. Flights can vary in a number of ways, including their pitch, taper, and shape.

- Pitch—The pitch is the distance between flight crests. It can remain consistent throughout the flight (standard pitch) or increase along the length of the flight, creating additional space for the fed materials as they are being discharged from storage vessels while controlling flow rate. A shorter pitch is used to slow materials that tend to flow uncontrollably when agitated.

- Taper— In a tapered flight screw conveyor, the flight width gradually increases. This provides additional space at the inlet, allowing lumpy material to be delivered evenly.

- Shape—Various flight shapes can speed or slow the flow of material, prevent compaction, or facilitate mixing and aeration. For example, ribbon screw conveyors have a gap between the inner edges of the flight and the shaft, allowing sticky products to move through more easily.

Benefits of Screw Conveyors

Screw conveyors are highly customizable, efficient, and simple. They provide a cost-effective way to quickly, smoothly, and gently move dry bulk product from one place to another. Countless variations make these machines suitable for many different types of products, from powders to sticky materials. Due to their compact design and flexible configurability, screw conveyors can be seamlessly integrated into almost any material handling operation, even in the face of space constraints.

Because of their simple design, screw conveyors are easy to operate and maintain, requiring minimal downtime for routine upkeep. Openable panels can make cleaning and maintenance even more convenient. Because of their ability to dramatically impact productivity at a low cost, screw conveyors have become an integral part of bulk material handling.

Choosing the Right Screw Conveyor

To choose the right screw conveyor design for your operation, it’s important to consider several factors, including material density, particle size, and capacity and flow rate requirements. Be sure to consult with an expert with experience in process flow design to determine the appropriate specifications for your operation.

Bratney delivers world class equipment and solutions for agricultural bulk goods like seed, grain, feed, and fertilizer. We partner with industry-leading manufacturers and apply our design expertise to increase productivity, efficiency, and profitability for our customers. To learn more, check out our blog.