Efficiency and Productivity in Animal Product Manufacturing: Leveraging Top-of-the-Line Equipment

Written by: Bratney

The animal feed and pet products industry is rapidly adopting advanced automation technologies to increase efficiency and productivity. This transformation is driven by several factors: labor shortages, competitive pressure, quality concerns, and advancements in automation capability. Adopting automation can empower companies to overcome the challenges that impact their ability to efficiently produce quality products.

The Challenges Facing the Industry

Companies in the animal feed and pet products industry face numerous challenges that impede productivity. Inside the facilities, labor shortages significantly affect operations, as essential roles like equipment operators and production line workers can be hard to fill and retain. Facilities with limited staff often struggle to meet demand while maintaining rigorous quality control and health standards.

The need to prevent disease transmission and avoid product contamination presents significant challenges for facilities. It can be difficult to meet expectations around traceability, safety, and animal welfare while maintaining the high productivity needed to protect profits and allow for growth.

Automation as the Solution

Automation can give animal feed and product manufacturers the edge they need to produce top quality goods efficiently and cost effectively. With the right tools and implementation, manufacturers can boost productivity and optimize their processes.

- Manual labor can be reduced by using conveyors, which streamline material flow between stations.

- Automated bagging machines eliminate risks to product health and safety that are caused by human error while also reducing labor needs and physical strain on human workers. These machines automatically and hygienically carry out the packaging process, inserting the product into the bag or pouch that is then sealed.

- Robotic arms can take over repetitive tasks like palletizing. Robotic palletizers help increase efficiency and decrease downtime while improving workplace safety. In the long term, these palletizers can help improve the overall operation of a facility, reducing labor costs and alleviating labor shortage concerns.

- Because the cleaning process can be critical to the quality of the final product, facilities should also consider utilizing dust control and automated cleaners.

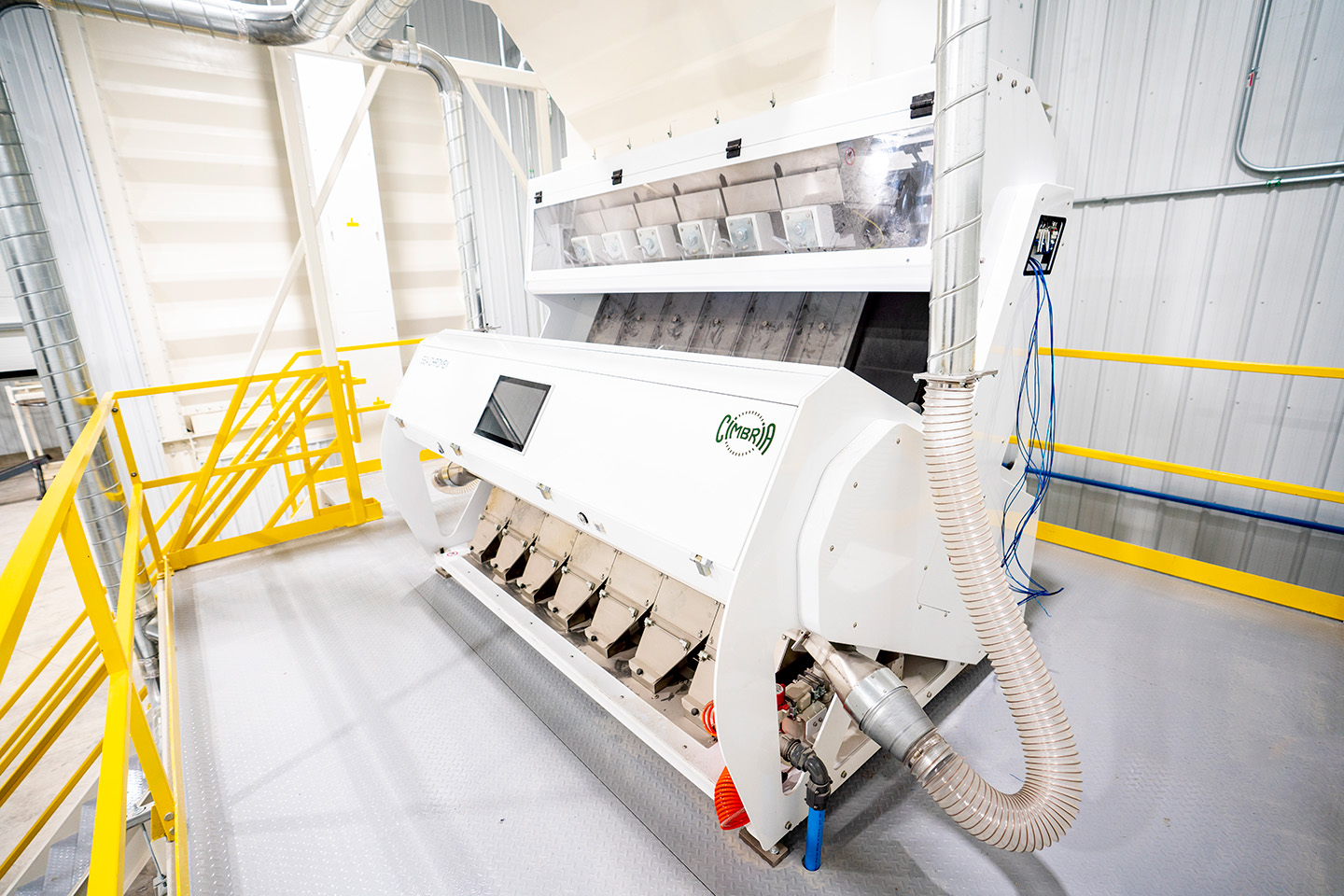

- Optical sorting technology goes beyond simply eliminating foreign materials; it is designed to identify and remove defective product (in this case, pulses).

These technologies and many more can help manufacturers increase productivity, improve animal welfare, reduce labor costs, and enhance data-driven decision-making. In these ways, automated solutions can be highly effective in addressing the major challenges facing the industry today.

Transitioning to Automated Operations

Automation is not just for new facilities. Established animal feed and pet product facilities can reap the benefits of automation. A specialized process engineering consultant can assess a facility’s current processes and pain points, laying the foundation for a customized automation solution. After the assessment, businesses can introduce a phased rollout, focusing first on the changes that will make the biggest positive impact.

Automation can make an immediate difference wherever it’s deployed. Automating the palletizing operation, for example, relieves workers of repetitive tasks that can cause strain and fatigue. Automated bag fillers eliminate human error in measurements, which can impact bag volumes or even product formulas. Machines can not only reliably perform tasks correctly but also keep accurate and detailed records to meet tracking requirements and other safety regulations, protecting manufacturers and consumers alike. By gradually implementing automation, facilities can adapt to the new processes over time while increasing productivity, reducing waste, enhancing safety, and improving efficiency.

The Path Forward: Consultative Solutions

Each company faces its own set of unique circumstances, including their business objectives and readiness to adopt new technologies. As a result, there is no universal automation solution for increasing efficiencies and enhancing productivity. For this reason, a consultative approach that spans from initial assessment through deployment and beyond is the best way to make the transition. When working with a consultant, a facility receives customized strategies that meet their specific needs and challenges.

A consultant will conduct assessments to better understand a facility’s workflow, pain points, and business goals to shape an automation solution that is intimately compatible with its specific environment and culture. These professionals can help companies scale automation based on needs and budgets while supporting workers through adopting and utilizing new technologies.

The Future of Efficient Automated Operations

Automation is essential for the animal feed and pet products industries. These facilities will be better off for adopting automated solutions to maximize productivity and efficiency. Automation can help businesses in the industry overcome the pressing challenges related to labor shortages, disease and quality control, and more.

Technologies like automated bagging machines, robotic palletizers, and conveyors offer transformative capabilities to maximize efficiency. Implementing these solutions does require a careful approach, but professional consultants can provide guidance tailored to each company’s unique circumstances.

For more information on how your facility can utilize automation, subscribe to our blog.